Dairy Industry: Maintenance

Machine maintenance at Sachsenmilch

At Anuga FoodTec, two key innovations are increasingly taking centre stage: condition monitoring and predictive maintenance. They promise proactive maintenance of individual components and entire systems. Smart sensors, big data, cloud services and machine learning approaches work together to optimise food processing in real time, ensuring machine availability. A glimpse inside the production halls of Sachsenmilch Leppersdorf GmbH shows what this looks like in practice. The dairy, located in Leppersdorf in eastern Saxony in Germany, processes around 4.6 million litres of milk every day, which corresponds to 170 lorry deliveries daily. Complex and in some cases fully automated plants are used to manufacture a wide range of products such as milk, butter, yoghurt, cheese and whey derivatives for baby food. In order to maintain this volume, smooth production operations 24/7 are essential. For this reason, the decision was made to carry out a pilot project at the site with Siemens Digital Enterprise Services.

Networked machines that produce vast amounts of data

The background: The production environment in Leppersdorf has modern, networked machines that generate large amounts of data – ideal conditions for a solution such as Senseye Predictive Maintenance. The predictive maintenance solution from Siemens enables cross-plant asset intelligence and eliminates the need for manual analyses. This enables food production companies to increase their productivity, operate more sustainably and accelerate the digital transformation of their entire organisation. These are goals that Sachsenmilch is also pursuing, as Roland Ziepel, Head of Engineering and Project Execution, reveals: "We utilise a wide variety of plant technology, and the Siemens solution enables us to respond before problems develop, significantly reducing production downtime. In addition, we no longer have fixed maintenance schedules, but instead base our maintenance on the condition of the system. And that naturally saves us maintenance costs."

Permanently monitoring critical drive components

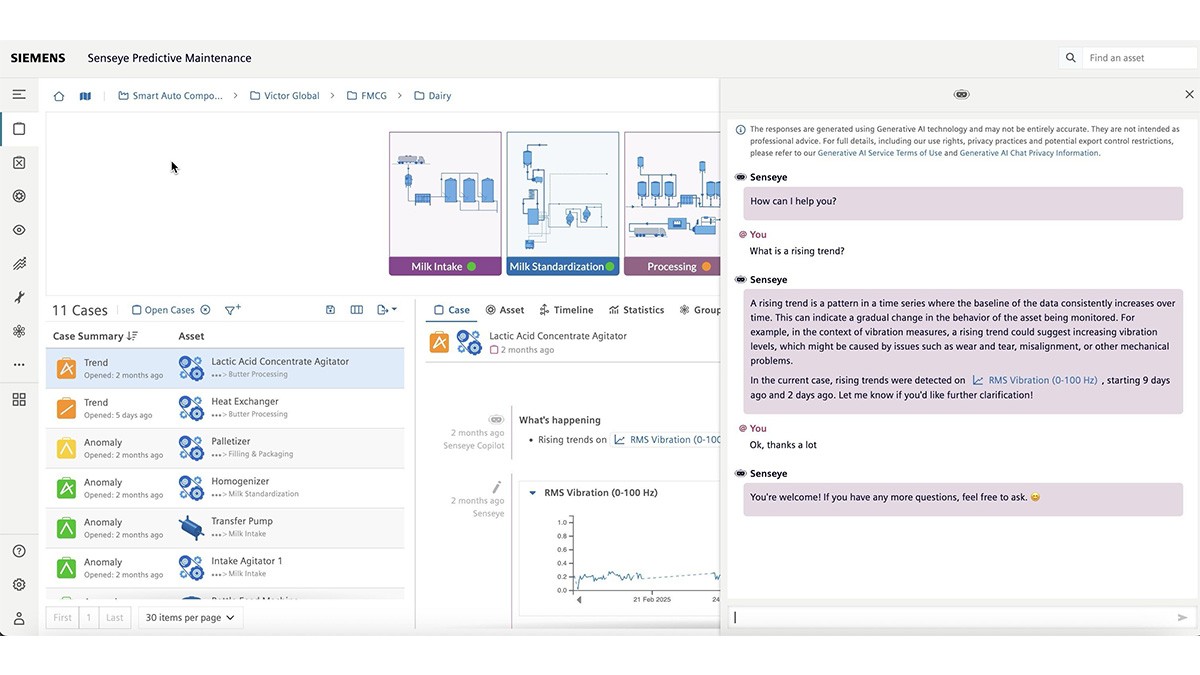

This is where the Siemens Senseye Predictive Maintenance solution shows its strengths: The platform combines powerful AI with human insights and automatically generates models for the behaviour of machines and maintenance personnel. This allows attention and expertise to be focused precisely on the most important points. It can be integrated into any plant, system or data source, whereby data that has already been recorded or newly installed sensors can be used as part of a complete package. This capability has already proven particularly valuable in Sachsenmilch's complex production environment during the pilot project. AI-supported algorithms can be used to initiate maintenance measures before the plant actually fails. One of the biggest challenges was therefore analysing the relevant plant data, such as temperature, vibration cycles and frequencies, in order to detect anomalies at an early stage and draw the right conclusions. To make this possible, the right data points were first defined in collaboration with experts from Siemens in order to be able to predict certain failure scenarios. In many cases, existing data from the control system could be used, while in some cases new vibration sensors and the Siplus CMS 1200 condition monitoring system were installed for vibration monitoring. It consists of at least one Simatic S7-1200 CPU, an SM 1281 condition monitoring module, and the necessary cables and vibration sensors for recording the relevant field data.

Replacement of a pump pays for pilot project

Siemens supported the maintenance team at Sachsenmilch with technical and project management expertise. “What we like about this project is that Siemens not only has expertise in technology and engineering, but also in project management,” says Ziepel, who was also responsible for project management at the Leppersdorf site. According to Ziepel, this made the collaboration much easier. Siemens' support in implementing the solution also served as training and introduction for Sachsenmilch employees, enabling them to continue the pilot project quickly and successfully on their own. The pilot project with Senseye Predictive Maintenance has already achieved significant cost savings through reduced unplanned downtime. "We can already say that the pilot project with Senseye Predictive Maintenance has paid for itself. The early detection of a defective pump alone has saved us a low six-figure sum in euros," concludes Ziepel.

Sachsenmilch planning next project

"We are delighted that we were able to successfully support Sachsenmilch with the introduction of a preventive maintenance strategy in existing processes using Senseye Predictive Maintenance. In this way, we promote efficiency and competitiveness in increasingly complex industries. And the further development of our maintenance copilot Senseye is another significant step towards transforming maintenance processes," said Margherita Adragna, CEO Customer Services at Siemens Digital Industries. Based on this success, the next project is already in the starting blocks: Together with Siemens, Sachsenmilch is planning to integrate Senseye Predictive Maintenance into SAP Plant Maintenance. The aim is to automatically receive maintenance notifications from Senseye in SAP PM, enabling them to be taken into account when creating maintenance orders. In addition, the Senseye maintenance copilot is to be used even more extensively in future. This will be a virtual maintenance assistant that can provide data-supported recommendations for necessary maintenance work. In doing so, it consolidates all the expertise of the maintenance team, stores all the necessary information about the equipment, for example in the machine manuals, thereby improving cooperation within the dairy.