Efficient protein extraction with radial flow chromatography

Project Launch and Technology Selection

The University of Poznań supported Polmlek in selecting suitable technologies for lactoferrin extraction. After thorough analysis of various methods, radial flow chromatography from Handtmann was identified as the preferred solution.

Albert Handtmann Armaturenfabrik GmbH & Co. KG, based in Biberach, has evolved over the past decades from a component manufacturer to a comprehensive solution provider for the pharmaceutical, biopharmaceutical, food, and beverage industries. As part of the internationally operating Handtmann Group with around 4,700 employees, the company combines decades of experience with innovation and close customer collaboration. Handtmann is thus a reliable partner for efficient, safe, and sustainable processes.

Radial Flow Chromatography – Fundamentals

Radial flow chromatography (RFC) offers key advantages over conventional column methods:

- Continuous operation with high flow rates

- Low differential pressure at high volume throughput

- Efficient scalability by adjusting column size

- High selectivity through specific adsorber materials

These features enable economical processing of large milk volumes while maintaining high product purity.

Pilot Testing and Process Development

Initial pilot trials were conducted by Handtmann in autumn 2023 at the Lidzbark production site. The goal was to validate the processability of available raw and auxiliary materials and to collect process data for later scaling.

- Pilot plant capacity: 1.500 liters per hour

- Setup: RFC column with agarose-based resin from Cytiva for selective binding of lactoferrin and lactoperoxidase

- Process steps: Loading, elution, regeneration

- Data collection: Throughput, adsorption behavior, elution profile, purity

The results confirmed the suitability of the technology for industrial scale.

RFC Pilot Plant - ©Albert Handtmann Armaturenfabrik GmbH & Co. KG.

Design and Construction of the Production Plant

Based on the pilot data, a production plant with a capacity of 900,000 liters of raw milk per day was designed. The extraction capacity is 45,000 liters per hour, resulting in a daily yield of approximately 75 kg of lactoferrin.

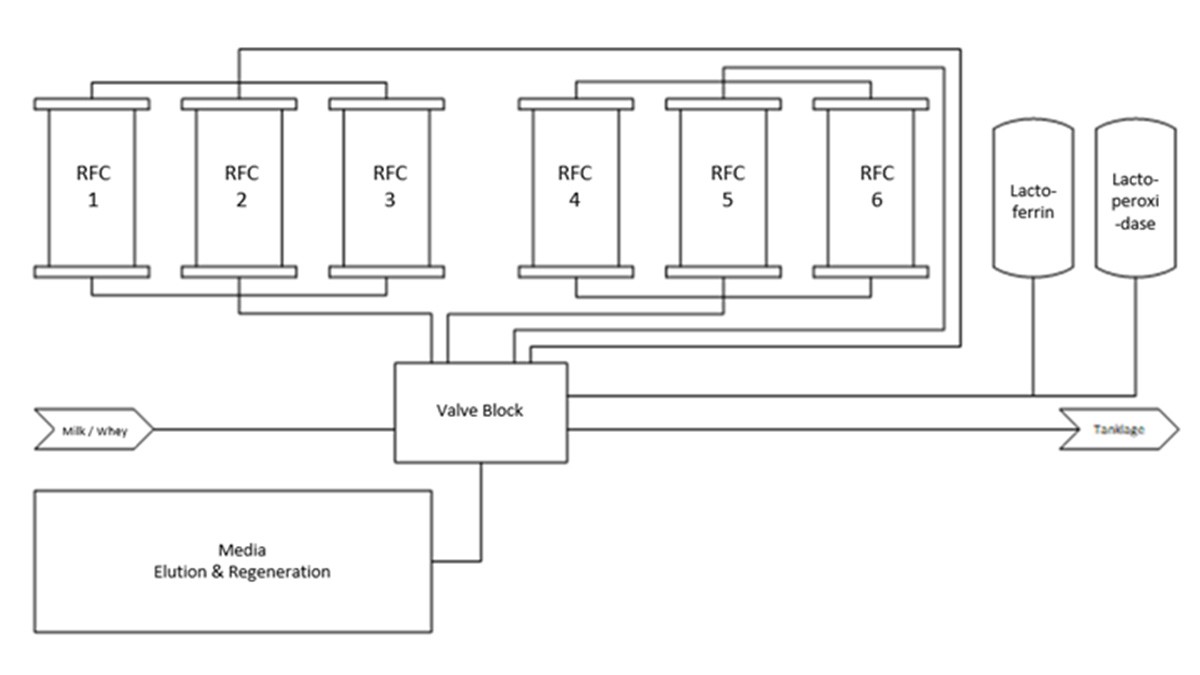

Plant Structure

Both separator-pasteurizer lines are connected to the extraction plant via a valve cluster. Two buffer tanks are used to decouple the systems, preventing mixing of water and milk during startup and shutdown.

The radial flow columns are arranged in two groups. While one group is loaded with milk, lactoferrin is harvested from the other and then regenerated. This allows for continuous operation, interrupted only by CIP of the separator-pasteurizer lines.

An agarose-based resin is used in the columns to bind lactoperoxidase and lactoferrin, which are eluted separately. The purity of the final product is determined during this step.

Elution: Required purity of >95% lactoferrin achieved in a single chromatographic step

Lactoferrin is cooled and collected in two chilled tanks. Lactoperoxidase is also collected in separate tanks.

System diagram - ©Albert Handtmann Armaturenfabrik GmbH & Co. KG.

Process Details

Adsorber material: Agarose-based resin with high selectivity from Cytiva

Elution: Required purity of >95% Lactoferrin achieved in a single chromatographic step

Resin regeneration: automated via elution skid

Salt recovery: Recycled into the process for resource conservation

Take-over valve matrix - ©Albert Handtmann Armaturenfabrik GmbH & Co. KG.

Results and Validation

The plant was successfully commissioned in early summer 2025. The performance parameters agreed upon in the purchase contract were significantly exceeded:

Lactoferrin purity: >98 %

Stable continuous operation

Minimized downtime due to CIP-optimized separator lines

High customer satisfaction: Order placed for a second identical plant at another site in Poland (planned commissioning spring 2026)

Radial Flow Columns - ©Albert Handtmann Armaturenfabrik GmbH & Co. KG.

Conclusion and Outlook

This project exemplifies how close collaboration between industry, academia, and technology partners can successfully realize innovative production processes. Radial flow chromatography has proven to be a powerful method for extracting functional milk proteins.

Polmlek plans to further expand the technology with Handtmann and extract additional bioactive components from milk. The combination of high product quality, process stability, and scalability offers great potential for future applications in functional nutrition and biotechnology.

Acknowledgments

We thank the University of Poznań for scientific support and all participating companies for their technical implementation.