High flexibility in spice production

A new level

"We are building Europe's most innovative factory for herbs and spices," was Euroma's aspiration for its new future milestone that was established in Zwolle in the Netherlands. The company, one of the leading producers of high-quality herb and spice mixtures and texture solutions, commissioned Daxner GmbH to engineer, manufacture and assemble a fully-automated plant solution in which the extensively tried-and-tested Daxner Container Handling System (DCS) plays a central role. Completed in 2019, the showcase factory covers an area roughly equivalent to five football fields, contains a 29-metre-high high-bay warehouse and has been awarded the 'BREEAM Excellent Sustainability Certificate'. First and foremost, however, it enables the Dutch spice manufacturer, which is a pioneer of gentle herb processing, to achieve a higher production volume and a new level of food safety.

Euroma brings together the drying processes of all of its existing production plants at its site in Zwolle. Daxner GmbH technology is also used at this location. Since its beginnings in 1984, the family-owned company, which has its headquarters in Wels, Austria, has developed into a global player in the bulk goods industry. "Daxner first came to our attention back in 2016 when we were preparing for a trade fair visit and came across a report about a reference solution that many of us found thrilling," says Euroma project manager Teun van Veen, recalling how the cooperation came into being. This was followed by a meeting and an initial pre-engineering order.

Contamination-free filling into the day silos is carried out via mobile sack and big bag intake stations. Vertical mixer in hygienic design (on right in figure). Copyright: © DAXNER GMBH

Ingenious container handling

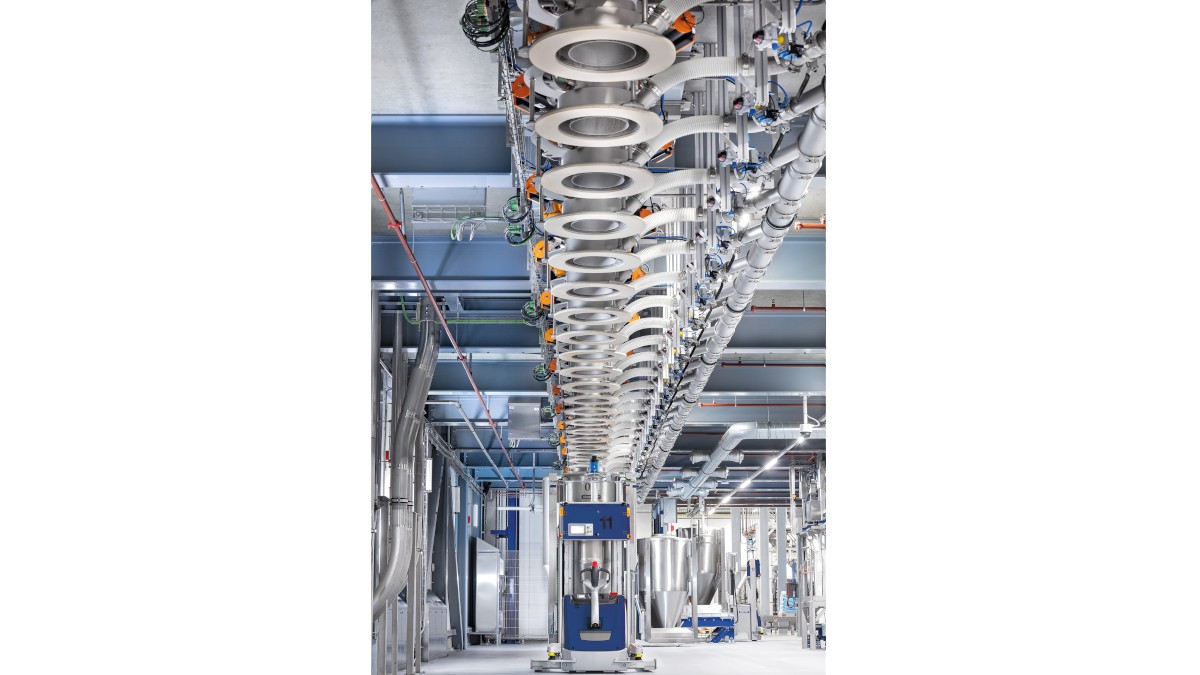

The design of Euroma's plant is technically impressive and meets high expectations of throughput, dosing accuracy and hygiene while avoiding cross-mixing and dust formation at the same time. All components are designed in compliance with hygienic design criteria and are manufactured from stainless steel. Inside the production plant, laser-controlled automatically guided vehicles (AGV) move in precisely choreographed interaction with the fully-automated Daxner Container Handling System (DCS) to collect the valuable dry components.

The raw materials are divided into large, medium-sized, small and very small components. Large components such as wheat flour or potato and corn starch are delivered in tanker trucks and stored in 12 outdoor silos. A pneumatic vacuum conveying system transports them to the day silos inside the building. The large and medium-sized components are filled into the day silos using mobile sack and big bag intake stations. High-precision scales are installed beneath the day silos. Depending on the product characteristics, separate day containers and a dedicated dosing and weighing system are assigned to these. This clear assignment prevents cross-mixing with allergenic raw materials.

At Euroma, containers are transported using automatically guided vehicles.

Feeding in the small and very small components

Once all of the individual raw materials have been dosed into the scales, the collection process takes place by means of the Daxner Container System (DCS) and combined automatically guided vehicles (AGV). To do this, a transport vehicle loaded with a 1,500-litre container drives from scale to scale and fills the container with the individual pre-weighed raw materials. This concept saves time, because dosing for the next container can take place immediately once a raw material component has been collected. On the ground floor, the small and very small components are fed into the containers. In keeping with the goods-to-man concept, all ingredients are brought to the operator: the containers by means of AGVs, the small components in sacks on pallets and the pre-picked very small components in crates from the small components warehouse. The system therefore optimises the supply time of all components without the operator having to cover unnecessary distances.

Once all of the mixing components have been collected, the containers are taken fully automatically to the mixing process. The containers are transported by AGV to the container lift and lifted to the level above the mixer, where another AGV collects them and puts them down precisely above the respective mixer. Both flap opening and emptying into the mixer are carried out entirely without an operator. Following the mixing process for herbs, spices and other ingredients, quality assurance is carried out for all products. The finished mixtures are weighed and filled into suspended big bags and then fed to the corresponding packaging lines.

The mixer and container sizes are optimally matched and offer extensive flexibility in terms of batch and production volumes (the figure shows container scales with a volume of 10,000 litres). Copyright: © DAXNER GMBH

Flexible thanks to different mixers

Mixers with capacities of 1,500 to 10,000 litres are used. Filling can be carried out directly from the outdoor silos or via the containers as well as by means of liquid dosing. In this case, the product is emptied directly into a downstream container after the mixing process. The mixer and container sizes are optimally matched and offer extensive flexibility in terms of batch and production volumes. This design freedom is also illustrated by another of the plant's highlights: the container mixer with a volume of 1,500 litres, in which mixing can take place directly without the necessity of transferring to a separate mixer.

Once the mixing process has been completed, an AGV collects the containers with the finished mixtures and transports them to the emptying station directly above the sack filling system. This is carried out in a fully-automated process without manual intervention by an operator. The finished mixture is filled into sales containers using gravimetric DAX-PVS series sack filling scales. The PVS dosing system (Pinch Valve System) consists of a pneumatically actuated rubber hose dosing system that enables the products to be dosed with high accuracy.

Fully-automated collection of the mixing components using automatically guided vehicles. Copyright: © DAXNER GMBH

Top quality and maximum safety

The entire plant is equipped with an aspiration system that minimises dust development and meets the required maximum standards of HAACP and IFS. A central de-dusting system has also been installed to enable quick and convenient cleaning in the manual areas. "We had a good feeling about this Daxner plant concept from the word go and were convinced that we were working together with a competent partner. No other company was able to offer us this concept as a complete solution, but it is precisely the overall concept that makes the plant so innovative," states project manager Teun van Veen, highlighting its success.

Further information