Hyperspectral imaging

Making the invisible visible

Can taste be assessed using imaging? It is hard to believe, because the chemical composition of food involves numerous possible variables, but: "Although the taste of food is not an immediately visible characteristic, the answer to this question is a clear yes in certain cases and if the right technology is used", says Minna Törmälä, Global Marketing Manager at Specim. The Finnish company has been part of the Konica Minolta Group since 2020. Performing such a task with conventional vision technology that "is limited to detecting characteristics and faults on the surface of the analysed objects is, of course, impossible" according to the expert, but it can be done with hyperspectral imaging (HSI).

AI-backed software and HSI cameras

Hyperspectral imaging will also be increasingly shifting into focus in quality assurance at Anuga FoodTec, because it can be used to determine quality-relevant parameters such as dry matter and the sugar, protein and fat content directly in the production line in a matter of seconds – without contact and without having to take samples. In addition to AI-backed software, focus is above all on HSI cameras. They make the spectral signatures of materials and compounds visible and enable the human eye to see what is invisible. They not only register the reflections of the light that hits the image sensor from the surfaces of an object and is recorded as the basis for subsequently recognising surface characteristics, but also enable the differentiation of the chemical and molecular structures of materials in the interior. "Using this technology in the food industry opens up new dimensions in quality control", says Törmälä.

Hyperspectral imaging is a combination of two-dimensional imaging and narrow-band spectroscopy. This technology enables the light intensity for each pixel to be recorded with a higher number of spectral bands. The cameras typically operate in the wavelength range from visible to near infrared light (NIR) and cover a recording spectrum of up to 250 spectral bands. Each pixel of the image is therefore given a complete colour spectrum, not just the three values for red, green and blue. "In this way, an object can be registered with significantly more details and greater accuracy, making the technology particularly suitable for quality assurance – to determine the characteristics inside the food that influence the taste, for instance", says Törmälä.

© Condi Food

Assessing tomatoes according to taste

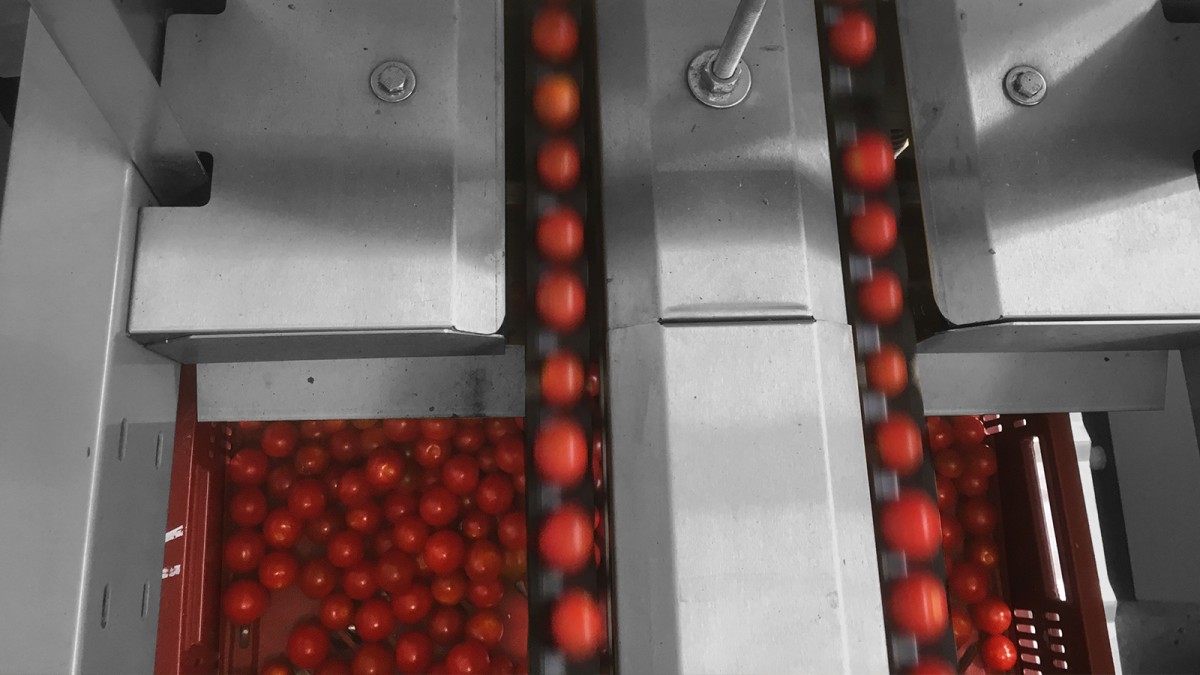

The background to this is that the chemical composition of food and characteristics such as the degree of ripeness, sugar content and acid content are crucial to the quality of the food's taste. And these are precisely the characteristics that can be analysed with hyperspectral imaging systems. The fact that HSI systems are able to assess the taste of food is confirmed by the Dutch company Condi Food BV, which is specialised in food quality and safety testing. "We have developed an innovative HSI solution for evaluating the taste of cherry tomatoes that can be seamlessly integrated into the sorting process during tomato harvesting", states Robi Nederlof, Managing Director of Condi Food, as an example. The chemical composition and the degree of ripeness or sugar content can be used to issue a statement regarding the flavour in real time.

The Specim FX17 hyperspectral camera, which is based on an InGaAs sensor and covers 224 wavelength bands in the NIR spectral range, plays a central role in this. InGaAs (indium gallium arsenide) is a semiconductor material that is renowned for its sensitivity to infrared light and which is particularly effective in the 900 to 1,700 nanometre range. "Many of the characteristics of fruit, vegetables and other foods that influence the taste can be analysed and assessed in this spectrum", emphasises Minna Törmälä. After imaging, suitable classification algorithms can be used to precisely analyse which substances are present.

© Specim

Hyperspectral camera as a key component

One of the special features of the Specim FX17 camera is that its recording speed can be flexibly adapted to the conditions of the respective application. It is possible to select only the wavelength bands that supply relevant information for the current application. This reduction enables the standard recording speed of the Specim FX17 to be increased from 670 lines per second to several thousand lines per second when using all 224 wavelength bands by only analysing the meaningful spectral ranges. This characteristic is termed 'Multi Region of Interest' (MROI). Besides the higher recording speed, MROI reduces the data volume and makes data processing and storage easier.

Selecting a suitable hyperspectral camera was the key step in developing the analysis system. On this basis, the HSI system is able to keep pace with the high production speed of 60 tomatoes per second on two parallel lines in the system implemented by Condi Food and enables the reliable detection of meaningful taste parameters without damaging or touching the vegetables. "This high level of efficiency enabled us to seamlessly integrate taste testing into the production line without any interruptions", emphasises Nederlof.

© Specim

Inspection detects defective food

Nederlof is convinced that Condi Food's successful project for analysing the taste of tomatoes shows that hyperspectral imaging also meets all of the technical prerequisites for analysing other types of fruit and vegetables as well as other foods: "HSI has become an important tool for advanced quality control in the food industry. In view of the challenges involved in producing agricultural products in greenhouses and increasing imports of fresh products, inspection is essentially important for upholding consumers' high quality standards."

The technology is also able to recognise bruised products that should not be consumed a few days later. Unsaleable products or expensive recall campaigns are possible consequences that can be avoided by using hyperspectral imaging. "Thanks to HSI, defective food can be sorted out at the producer and no longer has to run through subsequent processes such as packaging and the logistics chain to the customer. This leads to the use of fewer resources and a reduction in waste", says Minna Törmälä, summing up the benefits. She adds that analysing the taste of all types of food can also significantly boost a brand's sales. Törmälä: "Previously, tomatoes, peppers, strawberries, apples and many other agricultural products were sorted exclusively according to their size and colour, but perfect-looking fruit or vegetables do not offer any guarantee that their taste will actually meet consumers' requirements." If customers like the taste of the fruit or vegetables, however, they will choose the retailer again for future purchases. "The cost of investing in an HSI system for analysing taste can quickly be recouped in this case", says the Global Marketing Manager.

Further information:

www.specim.com