Increased efficiency in boiled ham production

Which physical mechanisms are used in trajectory mixing and to what extent do they guarantee homogeneous mixing?

Bernhard Hukelmann: Our mixers take an innovative approach to mixing materials, in which no conventional agitation tools such as blades, paddles or screws are used. Instead, the entire process container with the mixture is moved along a programmable trajectory. This movement, which is referred to as trajectory mixing, leads to the fact that the process material is accelerated and processes itself.

Andreas Leitze: The patented process is so efficient because it makes use of vibration principles and adhesive forces in the mixture. The movement of the container along a trajectory generates shearing forces that intensively mix the material. These shearing forces are distributed evenly throughout the entire volume of the container, because there are no mechanical agitation tools that could lead to localised load peaks.

The system uses what are called Lissajous curves ...

Leitze: Lissajous curves describe a physical phenomenon that occurs due to the superposition of harmonic vibrations that run perpendicular to one another. They occur due to two coordinated movements on the part of the process container. Precise temporal control leads to intersection points at which shearing and tensile forces occur. This enables the product to be mixed automatically due solely to the container's movements.

Hukelmann: In contrast to agitators, in which only a part of the material often comes into contact with the agitator, the entire process material is moved and processed at the same time in trajectory mixing – which enables particularly effective but gentle mixing, because the material is not subject to any direct mechanical effects.

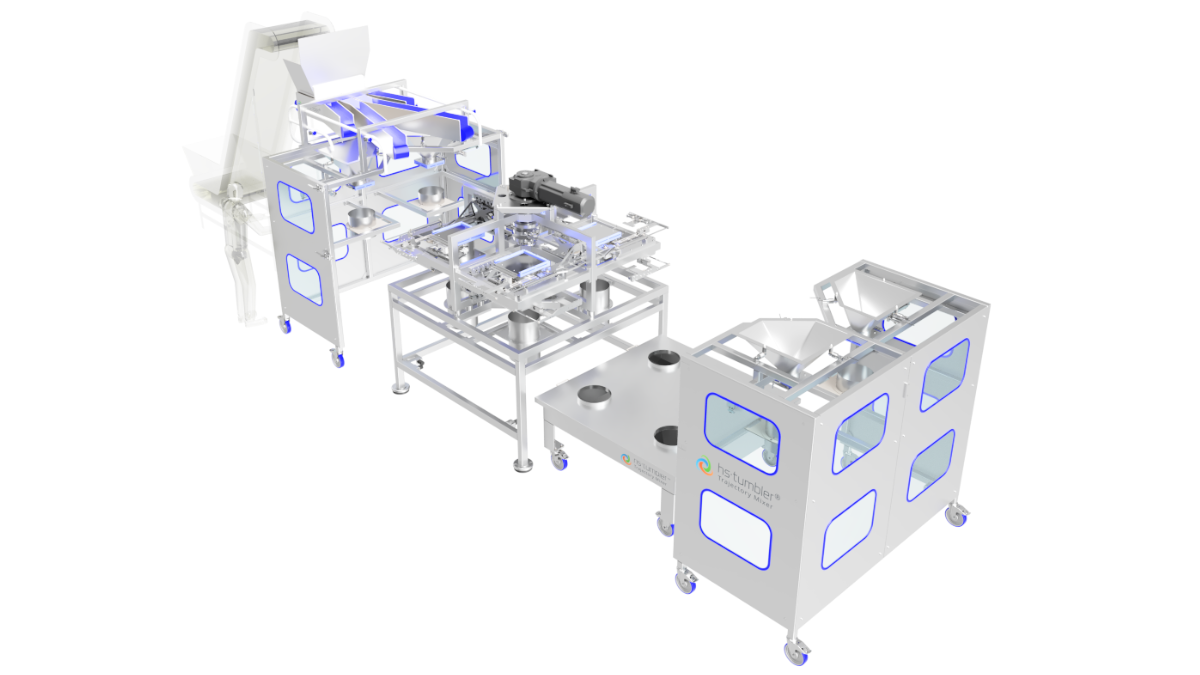

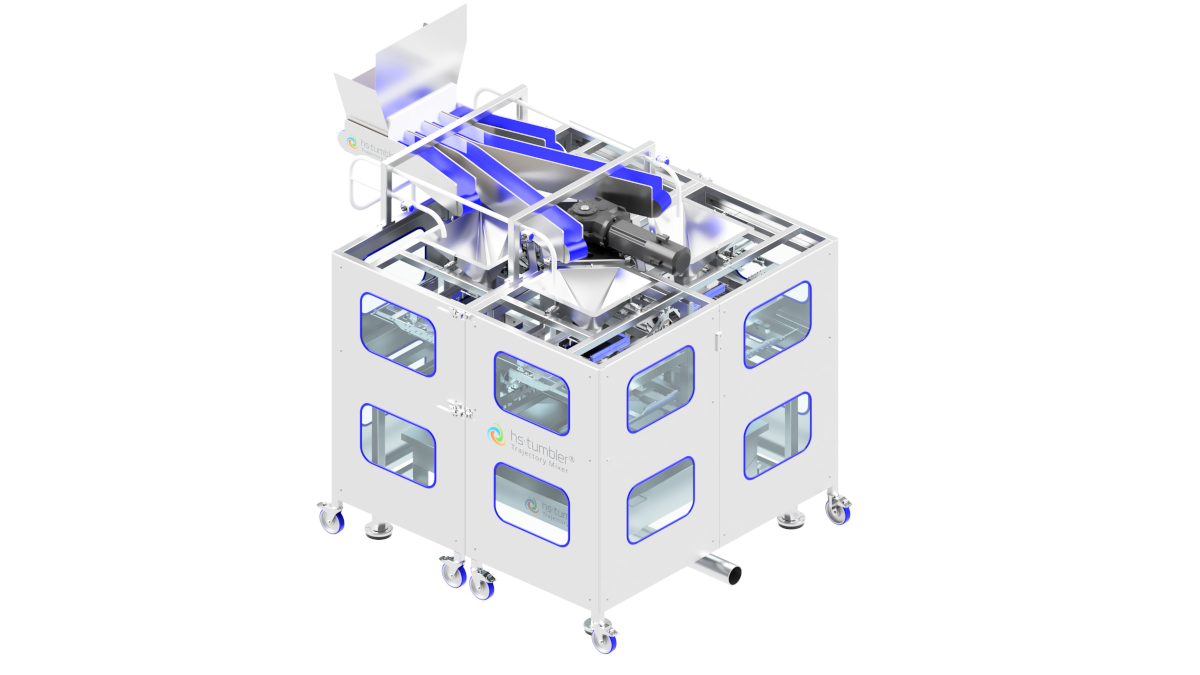

Ideal for medium to large industrial production volumes: the J4 system convinces with fully-automated container loading and throughputs of up to 7,200 kilogrammes per hour. Copyright: ©hs-tumbler GmbH

How can the mixing intensity be coordinated to the specific material? Which parameters can be adjusted?

Hukelmann: The Lissajous curves simulate the various stirring functions that are undertaken by whisks or dough hooks in conventional mixers. The specific characteristics of the Lissajous curves are dependent on parameters such as frequency, amplitude, phase angle and acceleration, and can be adjusted precisely to the viscosity and structure of the mixture.

Leitze: To give you a concrete example: in boiled ham production, trajectory mixing enables each batch to be processed individually – with specifically adjusted times, trajectories and brine dosing. All process parameters, the trajectories, frequencies and temperatures, can be programmed exactly and are logged. Smart sensors monitor the process, and remote maintenance and automatic safety shut-offs safeguard operation.

Your system has now successfully completed testing for industrial use at the German Institute for Food Technology (DIL). Which criteria did this focus on?

Hukelmann: The test runs focused on processing time, homogeneity and product quality in boiled ham production. The results confirm the very short processing times with consistent brine distribution and comparable yield and processability of the goods that are produced.

Leitze: We are talking about 7.2 tonnes of goods per hour in this case. Batch changes can be carried out in ten to twelve seconds, which is around 1,000 times faster than conventional processes. This not only improves hygiene and flexibility, but also enables manufacturers to implement new inline production methods.

Since the summer, the technology has been used in large-scale ham production at a food manufacturer for the first time. How exactly does the tumbling process function?

Hukelmann: The trajectory mixer offers the customer a revolutionary alternative because it efficiently combines several process steps in traditional boiled ham production. The meat is automatically fed into the receiving container and weighed. If necessary, the amount of brine specified in the recipe is added. It is then transferred to the process container and the HS tumbler begins to intensively mix and massage it. This ensures that the protein is broken down, the texture is improved and the brine is consistently distributed.

Leitze: The principle is like a black box: meat and brine are put into the container together, and the finished product comes out. Production can begin spontaneously, without any lead time, and our mixer delivers a virtually continuous product flow of just over seven tonnes per hour. With corresponding mechanical preparation, the injector can also be replaced if required.

Hukelmann: The individual process only takes around 20 seconds and enables virtually continuous production with consistent quality. NIR technologies can help to determine input and output qualities and therefore to always enable the optimum process. This not only offers the producer increased security.

Why is the injection of brine regarded as one of the most critical aspects of meat processing?

Leitze: In conventional methods, brine injectors with multiple needles are used to inject the brine directly into the meat. However, dosing is often inaccurate in this method and can lead to the leakage of fluid, as a result of which the risk of microbiological contamination increases.

What are the advantages of the trajectory mixer?

Leitze: The trajectory mixer offers a crucial advantage in this case: it makes injection unnecessary. Instead, the brine is incorporated completely and homogeneously into the meat in the sealed container by means of precise trajectory movements.

Hukelmann: The entire process material is in motion at the same time, as a result of which the brine is distributed consistently – without needles, without any return flow and without any hygiene or dosing problems. This not only reduces the risk of microbial contamination, but also leads to consistently higher product quality.

A type J4 industrial machine is in use at the customer's premises. What characterises this system?

Leitze: We offer the system in two versions. Both the J4-Flow and the J4-Base are available to customers as fully-automated systems. While the J4-Flow is specialised in high throughput volumes of over seven tonnes per hour, the J4-Base is focused on product variance with its two and a half tonnes per hour.

Hukelmann: The type J4, which is also in use at the ham producer, operates with four symmetrically moved containers to minimise energy consumption. Each container has a capacity of 15 kilogrammes of material, enabling the system to process 7.2 tonnes per hour with two batches of 60 kilogrammes per minute. The small volume of the containers minimises cleaning times and protein losses. The system is manufactured entirely from stainless steel and therefore meets the high hygienic design requirements within the meat industry.

Speaking of efficiency, how does the process affect energy consumption?

Hukelmann: In the same time, we can process three times the volume of the largest mixer currently available on the market, and our energy consumption is 80 percent lower. The design without mixing tools also enables quick and easy cleaning with minimum water consumption, which is another ecological and economic advantage.

Leitze: Thanks to this high resource efficiency, the trajectory mixer is also eligible for Federal Office for Economic Affairs and Export Control funding for numerous applications, which also makes the investment attractive for food producers.

Trajectory mixing made a real splash at Anuga FoodTec 2024 in Cologne and was presented with the International FoodTec Award in gold by an expert jury. Which challenges are you currently facing?

Leitze: As a start-up with innovative technology, there are various hurdles that we have to overcome: as the example of ham production shows, these include testing and verifying the mixing processes under industrial conditions, the establishment of a reliable service network and convincing potential customers of the systems' technical reliability. In the light of this, prestigious awards such as the International FoodTec Award are very important.

Hukelmann: Our process is used in food processing, and in the pharmaceutical, cosmetics and chemicals industries. 20 systems are in use around the globe, from the USA to Japan. In the next stage of development, we want to give our technology an additional boost by using artificial intelligence to dynamically optimise trajectory generation. It will also be possible to retrofit the AI in systems that have already been delivered.

hs-tumbler GmbH managing directors: Bernhard Hukelmann (left) and Andreas Leitze Copyright: ©hs-tumbler GmbH

Further information

Contact

hs-tumbler GmbH

info@hs-tumbler.com

https://www.hs-tumbler.com