Industrial washing of fresh produce

Eric Lefebvre is Technical Director and Managing Director of KRONEN GmbH. He is responsible for the company's technical development and innovation strategy and brings many years of experience in international food processing machinery manufacturing to the table. His focus is on hygienic design, automation, and sustainable production solutions that meet the high demands of the fresh-cut industry. Copyright: ©Kronen

Mr. Mottura, why has the EFSA conducted new studies regarding the topic of water hygiene when washing fresh produce, and what are its central findings?

Martín Mottura: The EFSA has produced a series of expert reports analyzing the microbiological risks involved in the use of process water when processing fresh and frozen fruit and vegetable products. The results of the fourth part of this series of studies, which focuses specifically on fresh-cut products, clearly confirm that without water disinfection, the microbial load increases significantly.

In five of a total of 19 industrial scenarios investigated, no disinfection was used – and the bacterial count was much higher. Furthermore, evidence of pathogens was only found in these five cases. The EFSA therefore emphasizes that effective disinfection can only be guaranteed with continuous monitoring of the disinfection parameters.

How does Citrocide® technology help ensure reliable disinfection?

Martín Mottura: The Citrocide® fresh-cut system is based on peracetic acid (PAA) and enables precise, automated, and continuous monitoring of the disinfectant concentration in the wash water. An integrated sensor measures the concentration in real time and ensures that it remains constantly within the optimal effective range.

Peracetic acid is particularly effective across a wide pH and temperature range, does not produce any hazardous by-products such as chlorates or trihalomethanes, and fully conforms with EU and U.S. regulations. It is also certified for use in organic farming and organic food production.

The connection to the digital platform CitroFy enables all data to be evaluated and remotely monitored, ensuring traceability and process reliability.

Mr. Lefebvre, how is this technology integrated into KRONEN washing machines?

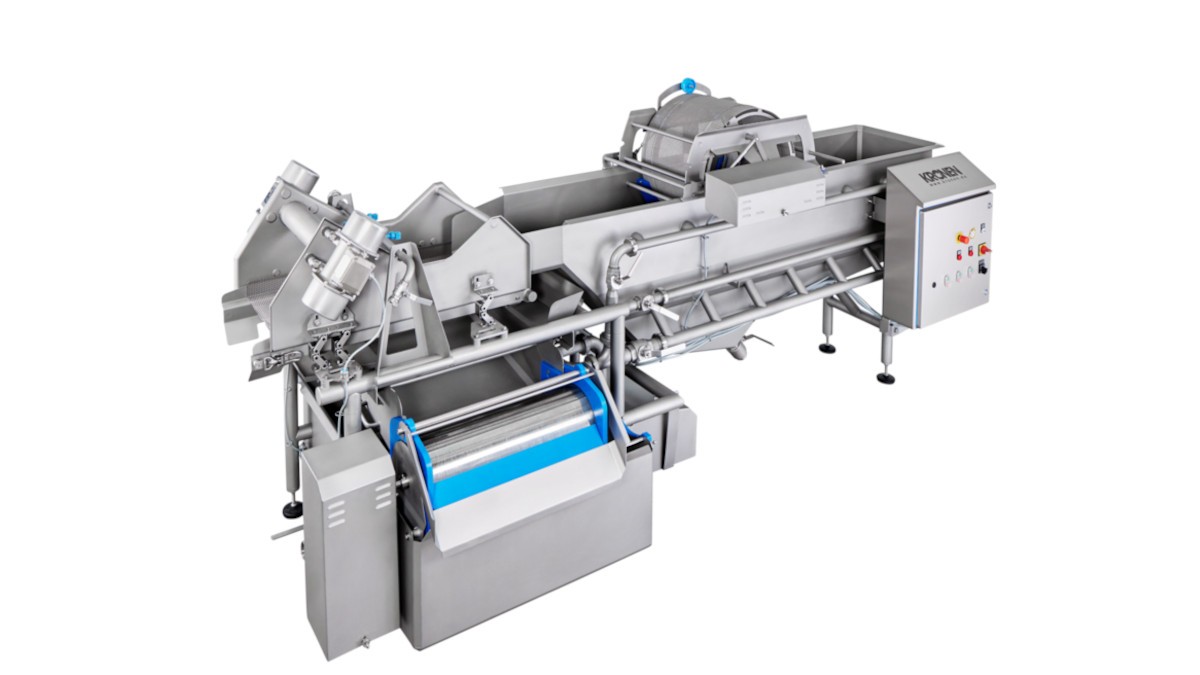

Eric Lefebvre: We can integrate and even retrofit the Citrocide® technology into all of our KRONEN washing machines. One example is the helical washing machines in the HEWA series. These machines have been developed especially for easy cleaning and the best possible hygiene, with optimal accessibility, smooth surfaces, and a hygienic design.

Combining them with the Citrocide® fresh-cut system facilitates automatic, reliable, and efficient monitoring of the water hygiene. The system continuously regulates the disinfectant concentration and the water renewal. As a result, we can ensure that the disinfection effect remains constant while optimizing water consumption at the same time. All in all, the joint solution developed by KRONEN and Citrosol enables a hygienic, efficient, and user-friendly washing process.

What are the differences between peracetic acid and chlorine in terms of their effectiveness and application?

Martín Mottura: Both substances are generally effective when it comes to disinfecting wash water and products. Peracetic acid, however, offers clear advantages regarding safety, environmental compatibility, and handling. While chlorine requires precise pH regulation, pre-rinsing, and post-rinsing, and regular concentration checks, peracetic acid remains stable and reliable without requiring any complex additional measures.

Furthermore, chlorine produces disinfection by-products (DBPs) such as chlorates or trihalomethanes, which are viewed critically, while peracetic acid breaks down completely into non-toxic residues, namely water, oxygen, and acetic acid. As a result, it is at least as effective as chlorine but much more sustainable and safer for humans and the environment.

Martín Mottura is R&D Manager at Citrosol S.A. and specializes in post-harvest technologies for ensuring the microbiological quality of fruit and vegetables. He works on the research and development of innovative sanitization and disinfection systems, including those based on peracetic acid solutions. Copyright: ©Kronen

What concrete advantages does this provide for processing companies?

Eric Lefebvre: Our customers benefit twofold: On the one hand, the products offer a higher level of microbiological safety, which is particularly essential in the case of delicate products such as salad leaves or cut vegetables. On the other hand, the system enables the sustainable use of water resources because it requires less fresh water.

The automatic control also reduces the use of chemicals, and the processes are documented to ensure traceability, which supports companies in their efforts to comply with quality and audit requirements.

KRONEN's HEWA washing machines (Fig. HEWA 3800 with vibration discharge) for salad, vegetables, fruit, herbs, and other foods are optimized for hygiene and easy cleaning. The design ensures maximum hygiene. Copyright: ©Kronen

How do you both rate the importance of the new EFSA results for the industry?

Martín Mottura: The EFSA has very clearly underlined that the disinfection of the process water is not an optional step but a significant hygiene measure. Without it, there is a risk of cross-contamination. Our technology shows that modern, monitored PAA systems can already meet these requirements in the present day.

Eric Lefebvre: I think that the results clearly confirm our joint concept. The combination of intelligent disinfection and hygienically designed machines offers our customers real added value, enabling them to manufacture safe, high-quality products while also saving resources.

The K650 drying system is designed for processing large quantities of cut salad, vegetables, and fruit. In a continuous processing cycle, the K650 can dry up to 2.6 tons of product per hour. Copyright: ©Kronen

What is your conclusion?

Eric Lefebvre: The cooperation between KRONEN and Citrosol combines the best of both worlds: mechanical engineering made in Germany and the leading hygiene solutions in Europe from Spain. With KRONEN Citrocide® PLUS, we are setting a new standard for safety, sustainability, and efficiency in the industrial washing of fresh foods.

Further informations: