Integrated Leak & Sealing Inspection

Real-time safety check

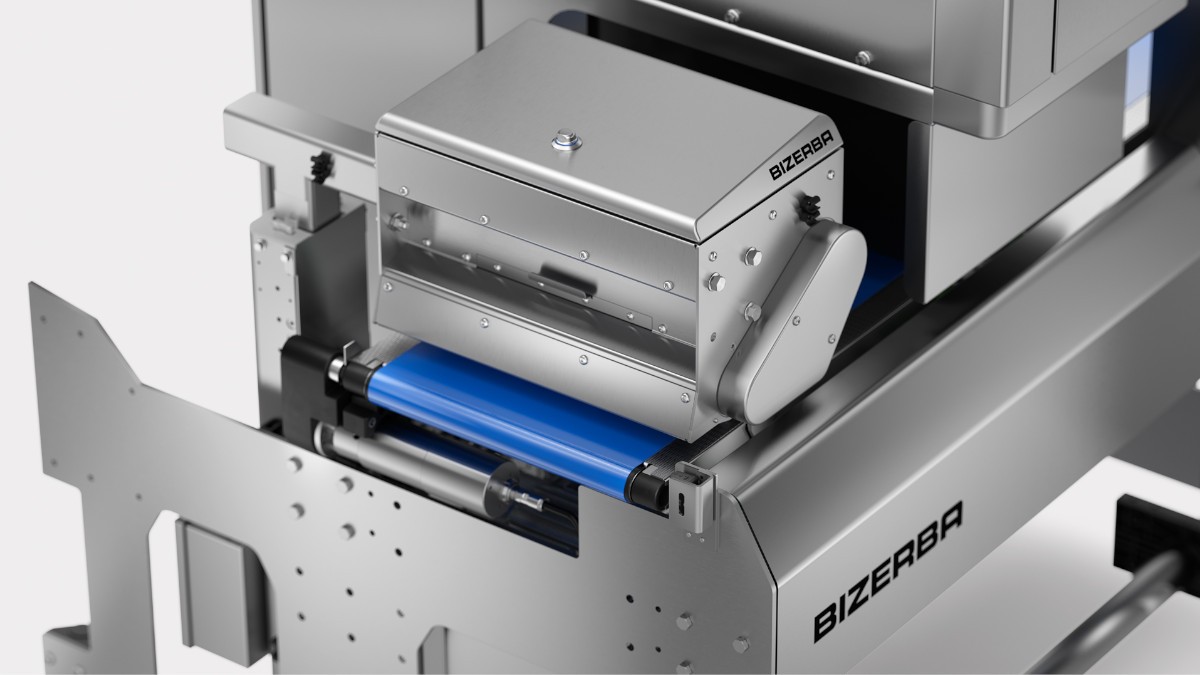

This is where Bizerba's LeakSecure comes into play. Designed as a compact inline testing device, it can be seamlessly integrated into existing process lines and automatically checks every single product package. Without any delay in processing, even the tiniest leaks in sealed product packaging can be detected, emphasises Bizerba. The sensitive CO2 sensor unit used for this purpose works independently of carbon dioxide fluctuations in the production environment, the manufacturer adds. The colour of the packaging and the temperature also had no influence on the test result, as LeakSecure is based on a mechanical function.

For inspection, the products are automatically separated and then subjected to a defined pressure in LeakSecure. This allows any gas leaks to be precisely located using several sniffers in a row, which are displayed on the monitor in real time for the system operator. According to the product development team, this would also allow important conclusions to be drawn about the cause of the leakage.

In May 2025, LeakSecure was presented to a wide audience of experts for the first time as a prototype. The great interest shown by visitors underscores the existing demand for innovative solutions in this area. Promising field tests are currently being carried out, including with customers from the meat packaging industry.

No chance for seams with sauce

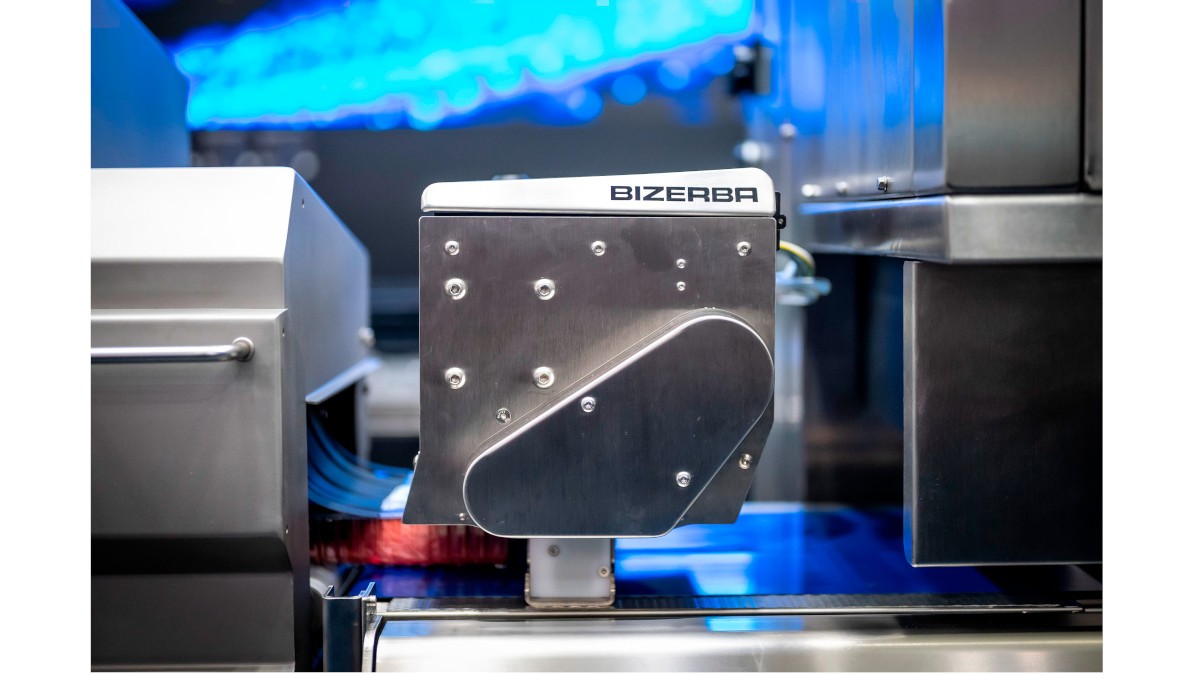

In line with this, this year the long-established technology company from Balingen, Germany has unveiled a new system for the automatic inspection of sealing seams – another weak point in food packaging. Even the smallest impurities such as crumbs, traces of liquid or creases in the seal are considered hygiene defects and can cause food to spoil more quickly.

Bizerba's SealSecure is a visual inspection device for clean, intact seams. By registering and displaying deviations from the respective specifications via ultra-fast data transmission, defective products can be immediately rejected and corrective measures initiated. Inspection takes place in real time at belt speeds of up to 90 m/min and is independent of ambient light or packaging transparency.

The LeakSecure leak tester from Bizerba. Copyright: © Bizerba

Quality assurance and cost reduction

The ability to rework product packaging at an early stage, if necessary, is a major advantage. This allows sealed food packaging to be corrected before labelling and prevents it from leaving the production line. This means: Cost savings and avoidance of recalls or food spoilage. The SealSecure also scores points with its compact design, complemented by automatic height adjustment and a simple user interface, which facilitates seamless integration into existing production lines.

Quality assurance includes the integrated BRAIN2 Capture software, which saves all images during production and generates regular production reports.

With the currently planned combination of LeakSecure and SealSecure, the leak test is performed first during installation using leak detection, followed by the seal seam test. However, Bizerba is also planning stand-alone solutions for the near future. As a further option, it is possible to combine a check of the packaging and labelling using the so-called PackSecure.

About Bizerba SE & Co. KG

Founded in 1866, this family-run company offers solutions for digitalisation, automation and networking, for example in cutting, weighing, labelling and inspection. Hardware and software, including apps and cloud services, are complemented by consumables, comprehensive services and flexible leasing options. Bizerba employs around 2,000 people in Germany alone.

Contact

Bizerba SE & Co. KG

Wilhelm-Kraut-Straße 65,

72336 Balingen

Germany

www.bizerba.com