No Breeding Ground for Germs

Hygiene places special demands on design

With components and systems designed for easy cleaning, plant manufacturers and producers ensure that neither microorganisms nor contaminants find their way into food. Only residue-free cleaning can ensure this. Both the choice of materials and the geometric design of the equipment are crucial in this context. Key factors include smooth, dead-space-free surfaces that do not retain product residues or cleaning agent residues, as well as the avoidance of crevices, cavities and areas that are difficult to access.

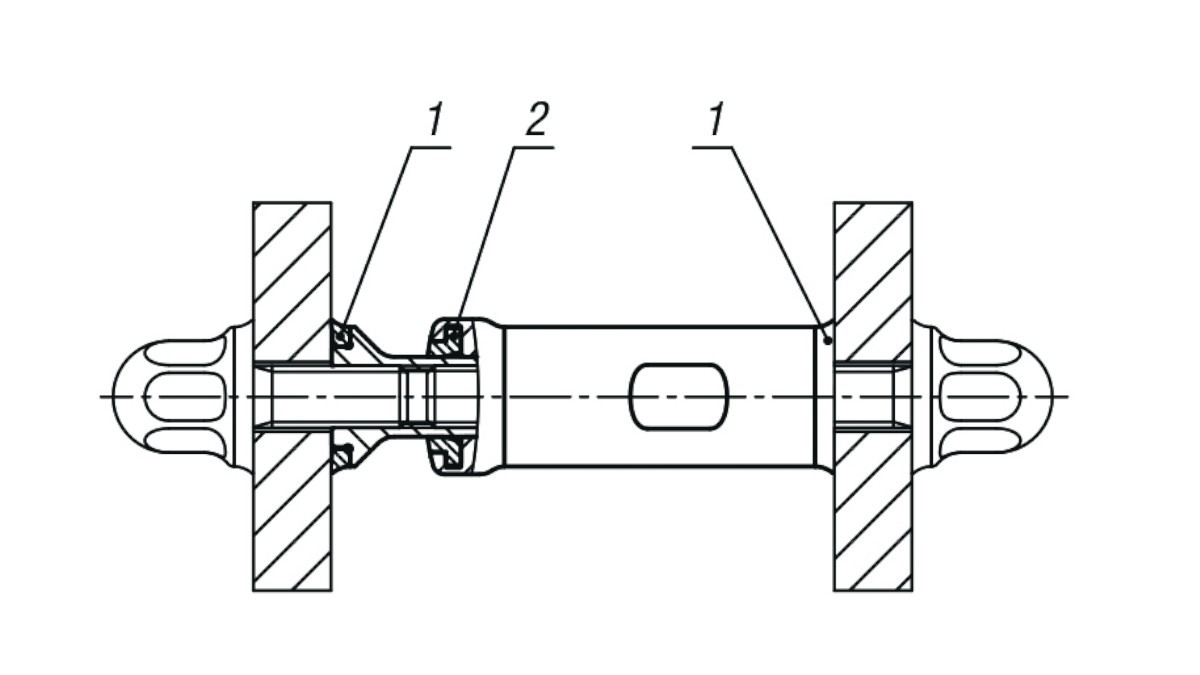

There is a Hygienic Design sealing ring (1) between the two end faces of the spacer and the components, which can be replaced if necessary. An integrated shaft seal (2) ensures process reliability by reliably preventing dust, dirt or moisture from entering the stainless steel cylinder. ©KIPP

Testing and certification of process engineering equipment

Product-sensitive systems in particular require components that can permanently withstand the stresses of multi-shift production processes and a wide variety of cleaning techniques. These include the use of foam, high-pressure jets or even high-pressure steam at different temperatures, pressures, chemicals and exposure times on the surfaces. This characteristic, known as cleanability, is a key aspect of hygienic design and a topic that is becoming increasingly relevant at Anuga FoodTec. The European Hygienic Engineering & Design Group (EHEDG) offers sound expertise in this area. It develops guidelines and methods for testing and certifying process equipment that comply with the latest research and technology in hygienic design. While it primarily tests components for cleanability in Europe, in the US it is 3-A that defines hygiene standards.

Class I components

The EHEDG makes a fundamental distinction between components that can be cleaned in a closed state without dismantling and those that must be dismantled for cleaning. The former are often installed in pipelines and cleaned there using cleaning-in-place (CIP) procedures. According to EHEDG specifications, they belong to the Class I component category. If cleaned with liquids (EHEDG certificate type EL), it is essential that corrosion-resistant materials are used. Class I components must be designed to facilitate flow, as they are flushed through during full flooding. Connections should be welded where possible. If detachable connections are necessary, they must be sealed with elastomers that are gap-free, as they are cleaned when closed. The PAC50 conductivity sensor from Baumer is an example of this type of measuring instrument. It is EL Class I certified and suitable for use in small manufacturing facilities, where it helps to save time, energy, cleaning agents and water. Its high temperature resistance up to 140 degrees Celsius enables permanent, reliable use in CIP systems. Baumer also offers other hygienic sensors for cleaning-in-place that measure parameters such as conductivity, flow, temperature, level and pressure precisely and quickly.

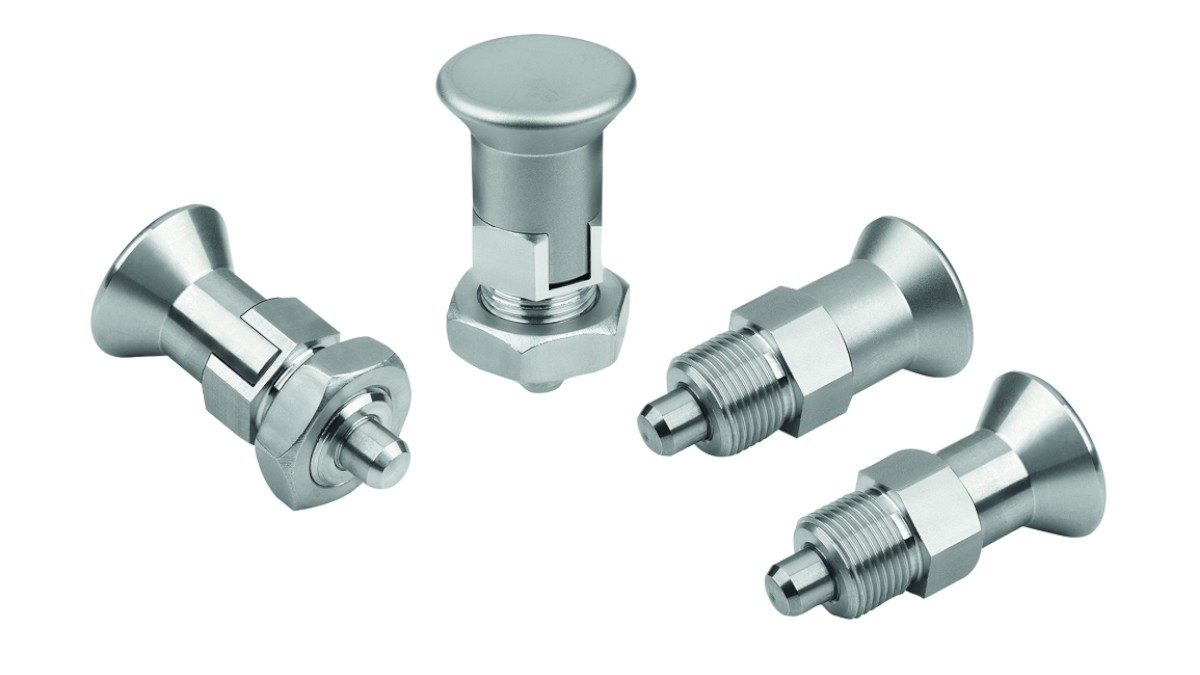

The new locking bolt with stainless steel mushroom handle from KIPP is available in two material qualities: A1 for simple applications and A4 for environments in which the component is subject to particularly high demands, such as in the chemical industry, shipbuilding or outdoor use. ©KIPP

Aseptic processes

To prove that components are not only easy to clean but also can be sterilised with steam and are impervious to microorganisms, the EHEDG uses three test methods: These consist of the cleanability test, which checks whether the measuring device can be cleaned using CIP, the sterilisability test, which confirms suitability for steam sterilisation, and the bacteria tightness test, which checks whether the component is hermetically sealed against the outside environment. Passing all three tests is essential for successful EL-Aseptic Class I certification (without disassembly). Components with this certificate are suitable for use in aseptic applications. A prime example of this is the pinch valve from the VMCE series by AKO Armaturen, which is listed by the EHEDG with an EL-Aseptic-Class I certificate.

When installed in pipelines, they either perform an absolutely leak-proof on-off shut-off function or can be used with an electro-pneumatic proportional valve for rough control or metering of a product flow.

Hygienic standard and operating parts

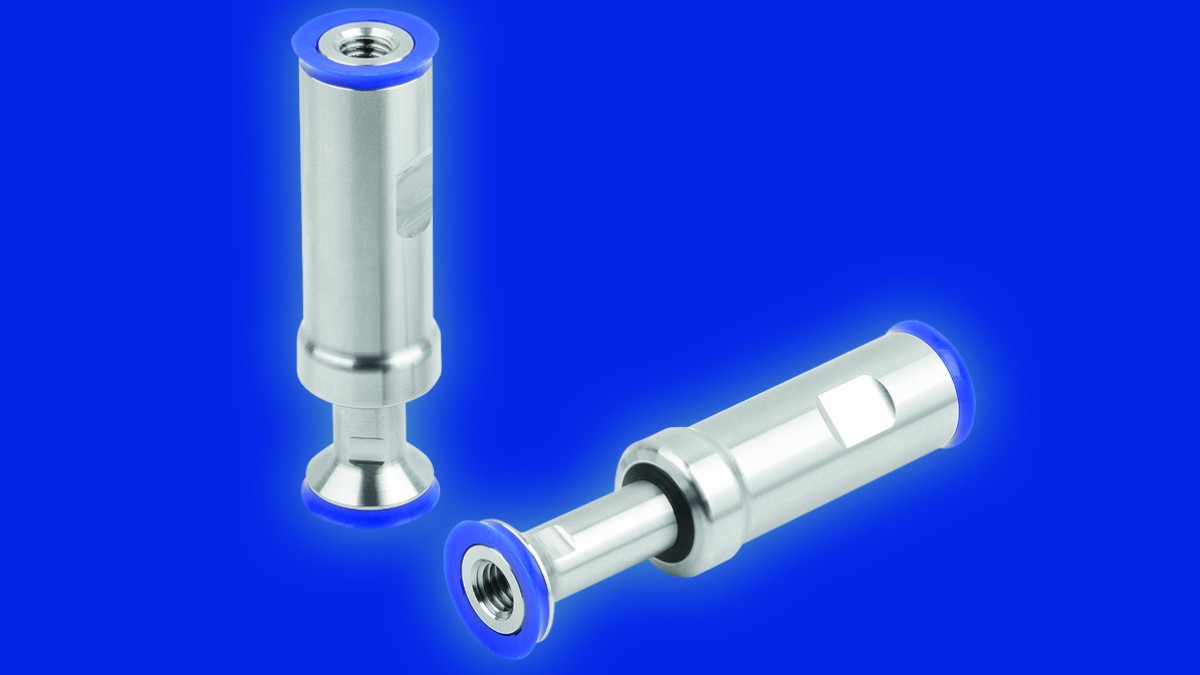

The EHEDG awards the EL Class I AUX certificate to components in open processes that can be cleaned with liquid without dismantling. Kipp offers just that with its Hygienic Usit K1594/K1595 screwing and sealing system. It was developed in consultation with Freudenberg Process Seals specifically for use in hygiene-sensitive areas. The screw head, nut, sealing ring and screw shaft are coordinated and together form a hygiene-optimised unit. This innovative product is ideal wherever hygiene is a top priority. These criteria were also applied in the design of the K2153 spacer. "With this product, we've found a solution that meets the demanding requirements of our customers in the food and pharmaceutical industries," explains Samuel Rasch, Team Leader Product Management at Kipp. "Thanks to its infinitely variable adjustability, smooth surface with a maximum surface roughness of Ra 0.8 micrometres and cleaning-optimised design, we combine maximum flexibility with the highest hygiene standards."

The original idea for the spacer arose from a special request: A customer required a flexibly adjustable support for an application with variable heights. What began as a one-off solution has been developed by Kipp into a product ready for series production. It allows the distance between two components to be adjusted continuously within a range of 20 millimetres. The spacers are suitable for use in a temperature range from minus 20 to 100 degrees Celsius. Process reliability is ensured by an integrated shaft seal, which reliably prevents dust, dirt or moisture from entering the stainless steel cylinder. There is a sealing ring made of EU10/2011- and FDA-compliant thermoplastic (POM) between the two end faces of the spacer and the components, which can be replaced if necessary.

The high-performance, easy-to-use process sensors of the 50 series from Baumer: PAC50 (conductivity), PT55 (temperature) and PP56 (pressure). ©Baumer

Stainless steel for greater safety

Stainless steel plays a central role throughout the food industry, especially in areas that come into contact with products. "However, complex hygienic design components are not always necessary in mechanical and plant engineering," says Rasch. "For many applications, simpler stainless steel components are sufficient – provided that the material quality and functionality are suitable. To ensure the latter, we recommend a detailed examination of whether the components are located in a critical working area." If this can be ruled out, solutions are available that are specifically tailored to the actual requirements. One example of this is the new locking bolt from Kipp. This is available in a short version with a stainless steel mushroom handle and optionally with an unhardened, hardened or chemically nickel-plated locking pin. There are two finishes to choose from: polished or matt blasted. That means the bolt fits in with existing systems not just technically, but also visually. This is a plus in machines with visible parts or in areas where cleanliness should be obvious to the eye. In the A4 version, the locking bolt is also non-magnetic or only slightly magnetic, which is advantageous for applications in sensitive areas.

WFurther Information

Baumer GmbH

www.baumer.com

Heinrich Kipp Werk GmbH & Co. KK

www.kipp.com

AKO Armaturen & Separationstechnik GmbH

www.ako-armaturen.de