Optical procedures for inspecting food

Which specific optical measurement processes are used at Polytec for analysing areas that are difficult to access – in the food industry, for instance?

Michael Huber: The next generation of process analytics includes near infrared spectroscopy (NIR): it is based on the interaction of light in the near infrared range with the molecules in the product. Depending on its chemical composition, the material absorbs certain wavelengths, from which important product parameters can be determined without contact or destruction in a matter of seconds.

Together with measuring units for contactless measurements above conveyor belts or with contact measuring heads for pipelines or storage containers, we enable quality-relevant parameters such as moisture, protein, fat or the sugar content to be measured on a 24/7 basis. The measuring units are compact and flexible in design so that they can be adapted to different installation situations. The spectrometer and sensor are separate and are connected by a thin, flexible control and optical fibre cable. This enables simple, space-saving and flexible integration into processes, even in areas that are difficult to reach in the production department.

To what extent do optical processes enable the non-destructive and, at the same time, precise analysis of food characteristics? Can you give us a specific practical example?

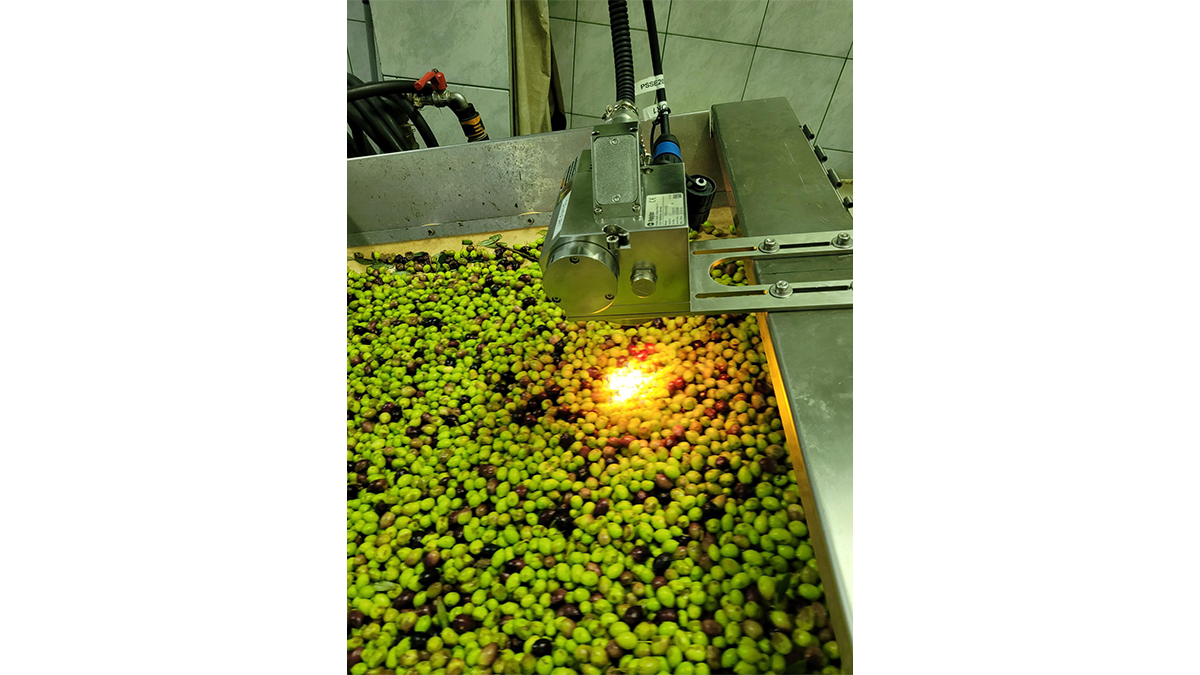

Michael Huber: Amongst other things, our customers use Polytec spectrometers in olive oil production. On delivery, the olives undergo non-destructive analysis on conveyor belts to evaluate their quality and oil yield. This enables a decision to be made early on as to how the subsequent production steps are to be structured.

Another measuring point is the residual oil content after pressing. This is where our compact measuring head, which is simply installed at the decanter outlet, shows what it can do. The measurement results enable extraction to be specifically optimised directly in the system.

Contactless NIR measurement of the supplied olives to assess the quality of the raw materials Source: Polytec GmbH

How do these optical processes differ from traditional measurement methods, especially with regard to efficiency, accuracy and sustainability?

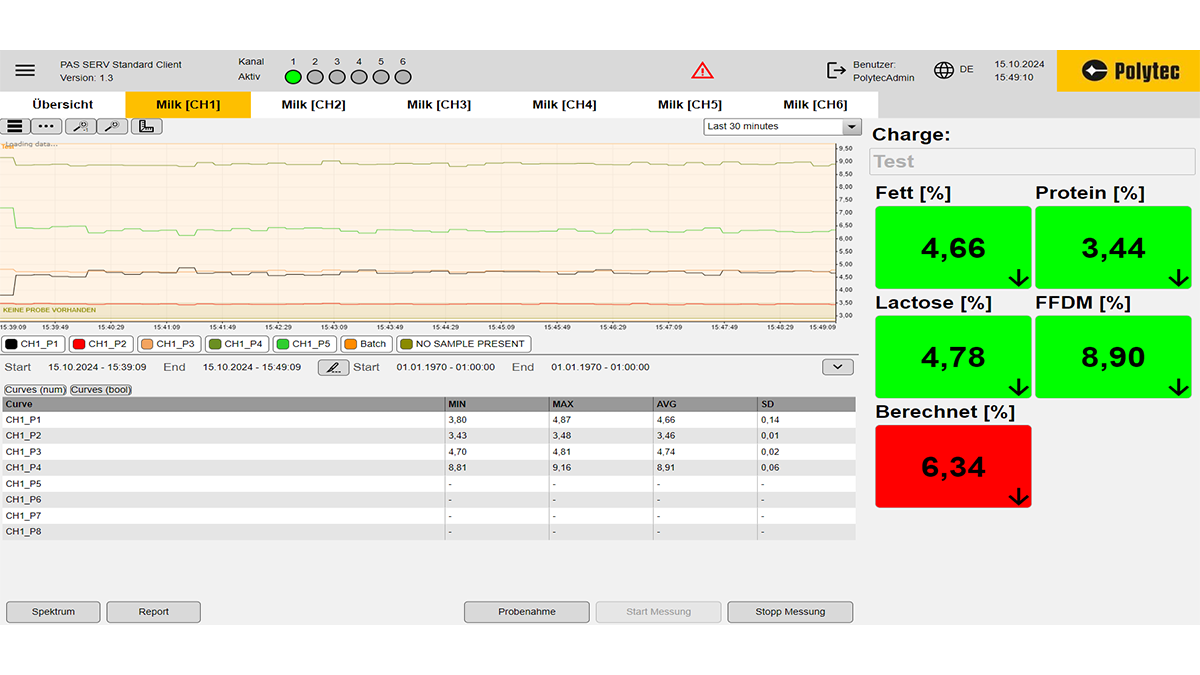

Michael Huber: Conventional wet chemical methods necessitate sampling, are time-consuming and produce chemical waste. Also, they often provide only localised results and are unable to continuously monitor the ongoing production process. Our optical methods are contactless, fast, environmentally-friendly and do not interrupt the process. The measurement results are output via a graphical interface. In this process, the software enables individual parameters to be visualised by means of a trend chart with a warning function. If overdosing or underdosing occurs in a measured value, it is immediately shown in the software and countermeasures can be immediately implemented to quickly and effectively balance out fluctuations.

What challenges are involved in contactless measurement in industrial environments – at high speeds in the production line, for instance, or in the case of different surface characteristics?

Michael Huber: The NIR measurement only takes a few seconds, but a compromise between speed and measurement accuracy is important at high conveying speeds. We achieve up to 50 individual measurements per minute and average the values in order to obtain a reliable overall picture of the raw materials that are supplied – olives, for instance. An additional issue is the surface characteristics: severely soiled olives are washed beforehand, and any impurities such as leaves, twigs or sand are removed. This improves the measurement accuracy. Consistent product characteristics are essential for precise analyses, particularly on conveyor belts – something that often poses a challenge with agricultural products.

Part of the irradiated light is reflected by the surface and the layers of the material that are close to the surface. The intensity and the spectrum of this reflection are dependent on the molecular bonds in the material – especially the carbon bonds. We use this to derive measurement parameters such as the oil content, moisture and acidity via corresponding calibration for the analysed product.

Polytec software for real-time analysis by means of NIR spectroscopy: visualisation of parameters such as fat, protein, lactose and dry matter measured in milk samples Source: Polytec GmbH

How can the real-time capability of these technologies be used for process optimisation, and what is the added value of this for producers and consumers?

Michael Huber: In contrast to classic laboratory analyses, NIR technology can be used to analyse the products delivered from an entire field, not just random samples. This enables a significantly more complete overview of quality fluctuations and increases product safety. At the same time, processes can be adapted and optimised quickly, which reduces raw material losses and increases cost effectiveness.

How do you see optical technologies evolving in the future, particularly with regard to their use in food processing or quality control?

Michael Huber: Optical processes such as NIR technology will continue to increase in importance. In view of growing population numbers and increasing cost efficiency, quality assurance and documentation requirements, producers can no longer afford waste or faulty batches. The trend is clearly shifting towards automated quality control with minimal staffing levels – an important lesson that has been learnt from the coronavirus pandemic. Future requirements in the food industry can only be met with system automation and continuous process monitoring.

Contact for further information

Michael Huber

Produktmanager, Geschäftsbereich Analytik

Polytec GmbH

Polytec-Platz 1–7

76337 Waldbronn

Germany

www.polytec.com