Refrigeration and Cold Storage Facilities

Mr Lange, temperatures of minus 25 degrees Celsius or colder are typical conditions in cold storage facilities. What opportunities does the use of fully automated storage systems open up, for example with regard to occupational safety?

Working continuously in extreme conditions, lifting and carrying loads is physically demanding. That's why strict break times are mandatory, shift work is compulsory, and regular check-ups are essential. Manual cold storage facilities experience high staff turnover, high staffing requirements and often a shortage of skilled workers. One of the most important advantages of automated storage systems down to minus 35 degrees Celsius is therefore the reduction in exposure to cold: Staff only need to enter the actual cold storage facility for maintenance work. Service lifts on the storage and retrieval machines and good accessibility to all components ensure that maintenance can be carried out quickly. Troubleshooting can often be carried out remotely.

... and in terms of process stability?

The automated conveyor and storage technology delivers consistently high speed and precision, reliably preventing damage to pallets and goods as well as malfunctions in the storage system. This enables faster handling of warehouse processes and reduces the time products spend outside the optimal temperature zone. Warehouse management and material flow control monitor batch security. This is crucial for an uninterrupted cold chain, for product quality and food safety – and, of course, for punctual deliveries.

What special considerations need to be taken into account for order picking in low temperature environments?

The goods-to-person principle has proven effective in minimising activities and walking distances in a low-temperature environment, thereby reducing the time required. It enables fixed, ergonomic picking stations and route efficiency in material flows. Depending on the products to be picked, this work can also take place in temperature-controlled areas of the building. In addition, all units and technologies must be adapted to low temperatures in order to protect against cold, frost and corrosion and to ensure high availability.

How does Westfalia address these challenges with its storage systems?

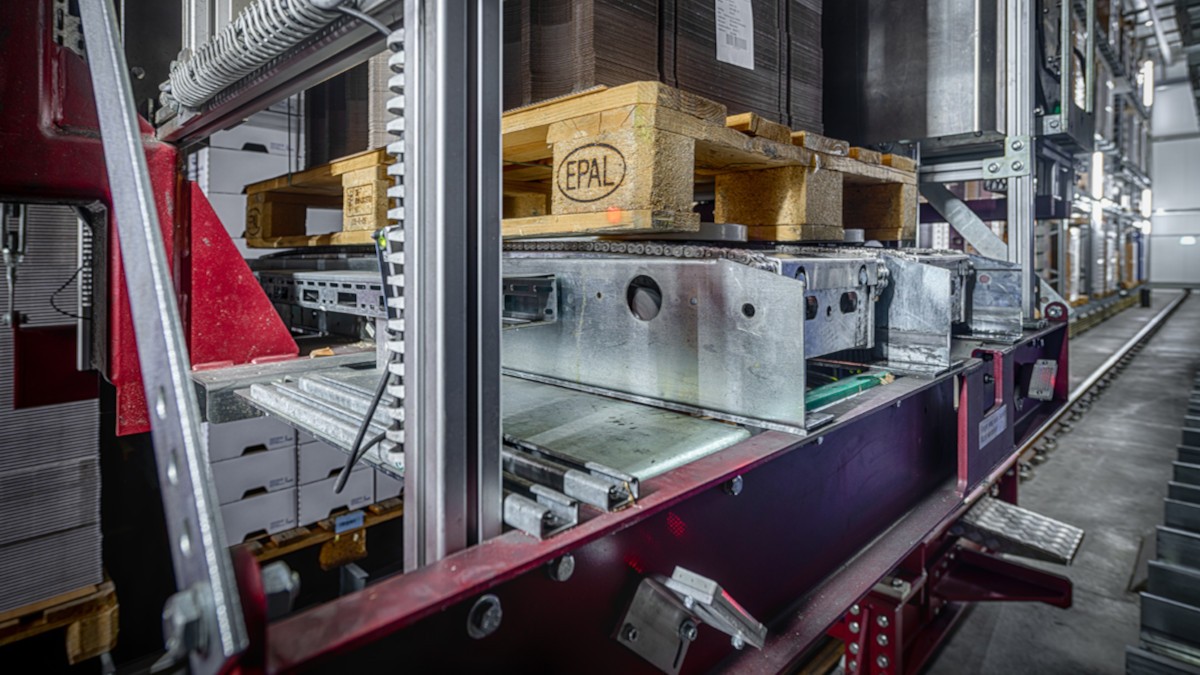

One of our key solutions is the patented satellite warehouse, which was launched on the market in 1983. Today, the Satellite load handling device is one of the most versatile technological kits for ultra-compact, multi-deep storage, even at low temperatures. Thanks to wired satellites, our warehouse technology is independent of batteries, which suffer significant performance losses in the cold storage sector. With our highly available systems, it's only really necessary to enter into the cold storage facility in extremely rare situations.

Thanks to their wide range of variants, satellites are suitable for various loading aids, requirements and types of storage. They store quickly, safely and without damaging materials. Photo: ©Westfalia Technologies GmbH & Co. KG / Marcello Engi

What other advantages does it offer?

Goods can therefore be stored at high density in storage channels of almost any depth, maximising storage capacity and space utilisation and enabling high transport speeds without damaging the goods. For example, additional storage profiles enable long service lives for disposable pallets.

Satellite warehouses can be customised as required and therefore implemented very close to production lines. This allows production and storage to merge, with raw materials, packaging or batches produced for stock being kept directly at the production site and transferred just-in-sequence. Our systems consequently significantly reduce costly set-up times and material transport distances.

With telescopic warehouses and satellite warehouses you offer two different types of warehouses. What criteria play a role in the selection of cold-storage products?

The selection of the right storage technology depends on several factors. In addition to obvious parameters such as the number of storage locations and throughput, storage density, batch sizes and article structures also play a role. Particularly in the food industry, these parameters favour the use of satellite warehouses. Storage density is a compelling argument, as cooling the storage facility requires a great deal of energy and every cubic metre of storage space saved reduces costs.

When is it advisable to use which type of storage?

In principle, satellite warehouses can achieve high throughputs with a higher storage density. Telescopic fork racks are primarily suitable for a very small-scale product range with small batch sizes, as they allow direct access to each pallet. Compared to shuttle systems, which are particularly popular for the high-frequency trade, our storage systems are a genuine alternative due to their robust technology and high cost-effectiveness in terms of procurement and system cycle.

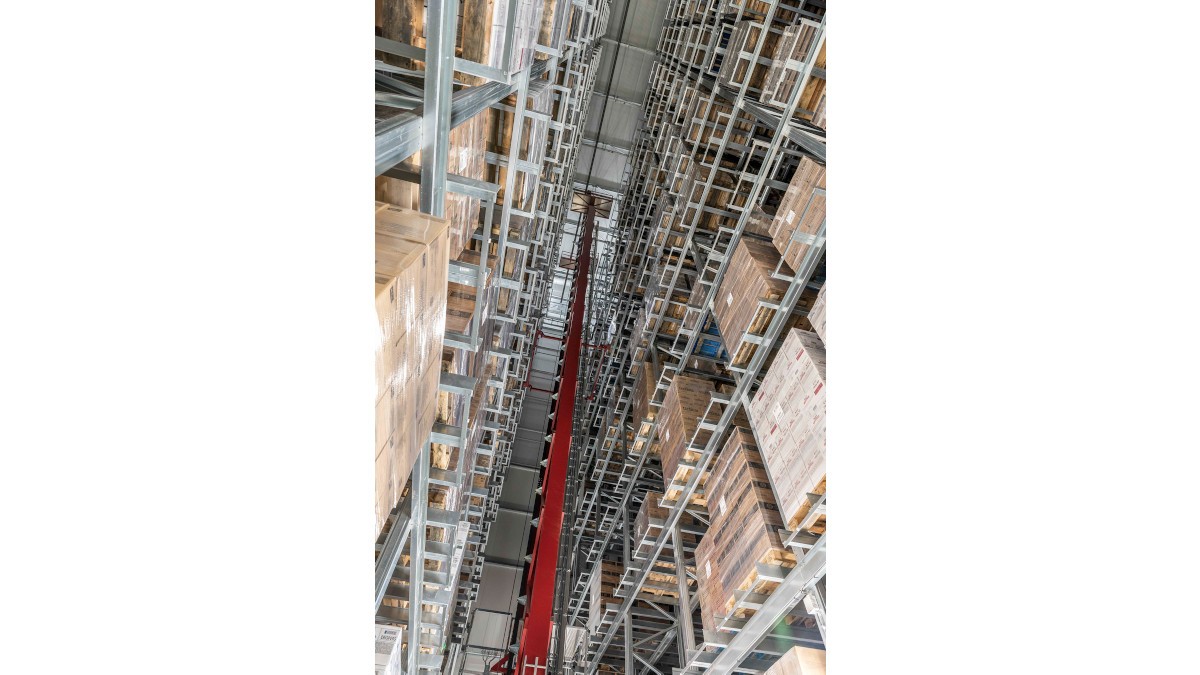

In large storage systems with up to 100,000 storage positions, many logistics threads converge to form a massive high-performance transshipment hub. Photo: ©Westfalia Technologies GmbH & Co. KG

How can the flow of materials between production and high-bay warehouses or dispatch be intelligently controlled?

By creating a virtual twin of the warehouse that accurately maps individual business processes, accelerates and shortens material flows, and makes them safer, more space-efficient and completely transparent. In addition to the system-related advantages already mentioned, we have also found a clear formula on the software side: The number of software systems that need to communicate with each other, thereby reducing the source of duplicate data and communication errors. Instead of one system for material flow control and another for warehouse management, we combine all these functionalities in an all-in-one software solution, our Savanna.NET Warehouse Execution System.

When is it advisable to use a warehouse execution system?

The simple answer: Always. In the first step, this may simply mean digitalisation, i.e. saying goodbye to order slips and picking lists. Processes and tasks such as transport or picking can be automated in further steps. However, the fundamental aim is to analyse existing processes and map them using a single system. A WES minimises the error rate, reduces the training time and familiarisation time for employees, while also reducing maintenance costs. With a system like this, entire storage clusters can be managed simultaneously and updated cost-effectively using software.

Why does it make sense to use a uniform system in the warehouse instead of different individual solutions?

It is always advantageous when the same system processes the data from the warehouse, issues instructions to the warehouse component and clearly prepares this data for all enquiries. If, on the other hand, a company uses many different individual systems with potentially error-prone interfaces and different user interfaces, the error rate, training time and costs increase.

Westfalia storage systems can be tailored to limited floor space and integrated close to production lines, even in existing facilities. Photo: ©Westfalia Technologies GmbH & Co. KG / Marcello Engi

Apart from storage technology, reducing energy costs plays a particularly important role in frozen food logistics. How does automation help to reduce energy consumption and CO₂ emissions?

Automated high-bay warehouses with maximum storage density and the associated material flows can be built very high and compact on a minimal footprint or integrated into existing buildings. This reduces the area and volume to be cooled per pallet space, improves energy efficiency and lowers costs. Automation reduces heat input and cold loss during storage and retrieval, as only the pallet passes through a minimal opening instead of a forklift, which draws in warm air and expels cold air with the resulting airflow. Compact storage with satellites reduces the number and size of aisles required to a minimum and significantly reduces the area not used for storage. Storage systems, such as those for Wernsing Feinkost or Lineage Logistics, combine up to 100,000 storage spaces in this way on a minimal floor space. This highlights the second, most important advantage in reducing energy costs and CO2 emissions: massive logistics consolidation.

What other requirements are currently having the strongest impact on developments in frozen food logistics?

From our perspective, digitalisation, resilience and sustainability. Digitalisation will always be about streamlining processes, reducing costs and increasing efficiency. Artificial intelligence will continue to open up new opportunities for further optimisation in the future, for example in demand forecasting, inventory planning and route planning. In connection with AI, the topic of cybersecurity is also becoming increasingly relevant, as attacks on companies' IT infrastructure are steadily increasing.

Contact

Moritz Lange

Vertrieb Technologien & Systeme

Sales Manager Technologies & Systems

Westfalia Technologies GmbH & Co. KG

westfaliaeurope.com