Smooth Material Flow

Components for conveyor systems

Whether aluminium cans, PET bottles or glass containers: Today's modern conveyor systems in the beverage industry have to overcome a number of hurdles, including varying product sizes, changing shapes, demanding materials and environments. Where slimline cans and lightweight bottles are increasingly replacing heavier formats, there are also new challenges with regard to the conveyor behaviour of the containers. Each new format is decisive in determining how steadily they move along the tracks through the factory. Modular designs and components that enable rapid adaptation are the key to maintaining smooth system operation. The experts in conveyor technology offer a comprehensive product portfolio for this purpose.

Designed for tight transfers

Logistical sensitivity is required, especially when numerous empty containers are transported to the filling plant every day. The transfer between conveyor lines is one of the most failure-prone areas of material flow. Conventional transfer plates often cause lightweight containers such as empty cans to get stuck, fall over or become damaged. The consequences are congestion, waste, unplanned downtime and higher personnel costs. With the introduction of modular plastic conveyor belts for tight transfers, Intralox presents a technical advancement that addresses these weak points. The knife edges of the conveyor belts are designed to eliminate the need for transfer plates. This means: The edge of the belt is so thin and precisely adjusted that the products transfer almost seamlessly from one belt to the next. To ensure precise alignment, the knife edge transfer units are pre-assembled.

Secure transport of the conveyed material

However, if a product does not run smoothly on a conveyor belt, there is rarely just one cause. Often, it is small deviations in the guidance or insufficient support of the structure that lead to malfunctions. With its modular product range of components for conveyor systems, Kipp offers the necessary flexibility to meet these challenges. It is a modular solution that can be adapted to different materials and plant environments. The main components include adjustable side guides and supporting components such as pipe connectors or support elements for conveyor belts. They ensure precise alignment and secure guidance of the conveyed goods – tailored to their size, shape and material. This allows changing product ranges to be transported safely without the need for costly modifications. The modular system is designed so that the components can be integrated into existing systems or configured for new projects. The modular design allows individual components to be replaced or expanded as required.

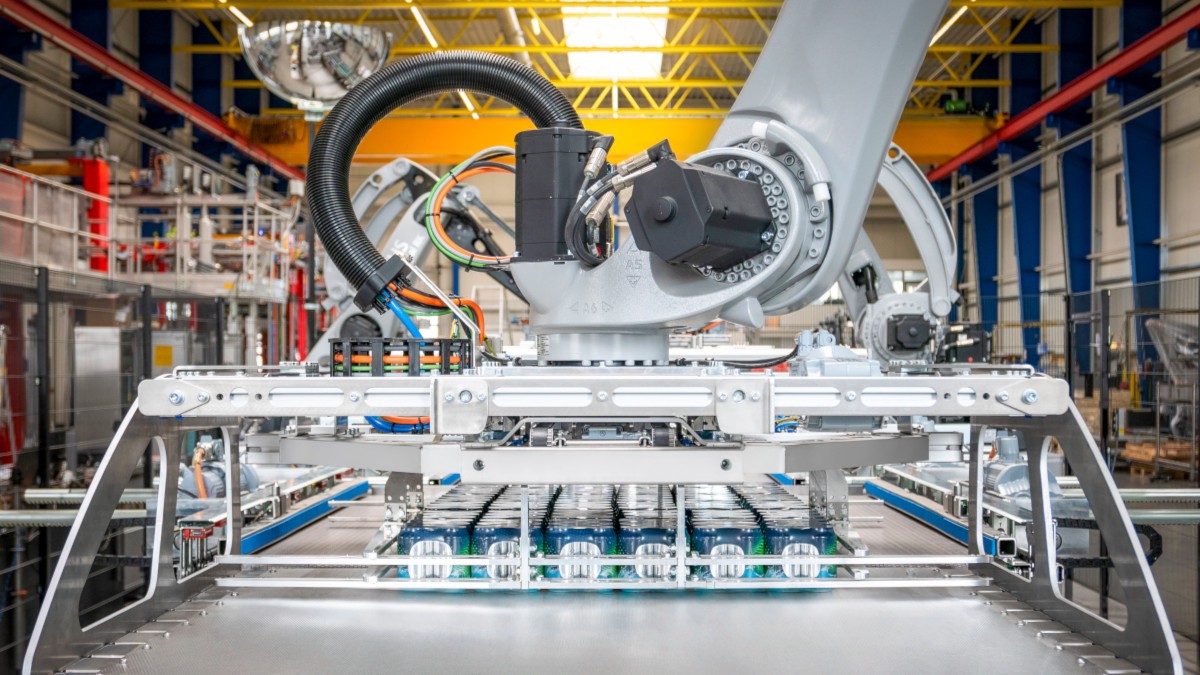

With the advanced Innopal PLR, line outputs of up to 240,000 containers per hour can be achieved using a single palletiser. Copyright: © Frank Reinhold

Adjustable for different scenarios

The side guides are made of lightweight, corrosion-resistant plastic (PE-UHMW). This ensures minimal friction between the guide and the product, enabling the gentle transport of sensitive goods. Various holder and clamp variants are also available. Single or double clamps provide the right hold, while height-adjustable flat irons enable millimetre-precise adjustment. The support elements offered prevent deformation of the structure and ensure precise alignment of the conveyor belt. The pipe connectors on the support elements are designed for standard diameters of 48.3 millimetres and 60.3 millimetres (DIN EN 10220) and enable stable cross-connections and modular adjustments. Depending on the design, the load capacity ranges from 1.5 to 9.6 kilonewtons. The range includes two- and three-legged base elements, T-connectors and support heads. All components are made of corrosion-resistant, durable materials.

Without interruptions and damage

Conveyor technology as the central link in beverage production that operates between filling, packaging and palletising, enabling a smooth flow of materials without interruptions or damage: KHS demonstrates this with the Innopal PLR for automated palletising of PET and cans. "The Innopal PLR is an innovation and a flagship product for KHS palletising technology," says Product Manager Ralf Kretschmann. It has been designed with the latest generation of robots for a throughput of up to 650 layers per hour in the high-performance range. This means that line outputs of up to 240,000 containers per hour can be achieved using a single palletiser with high stacking accuracy.

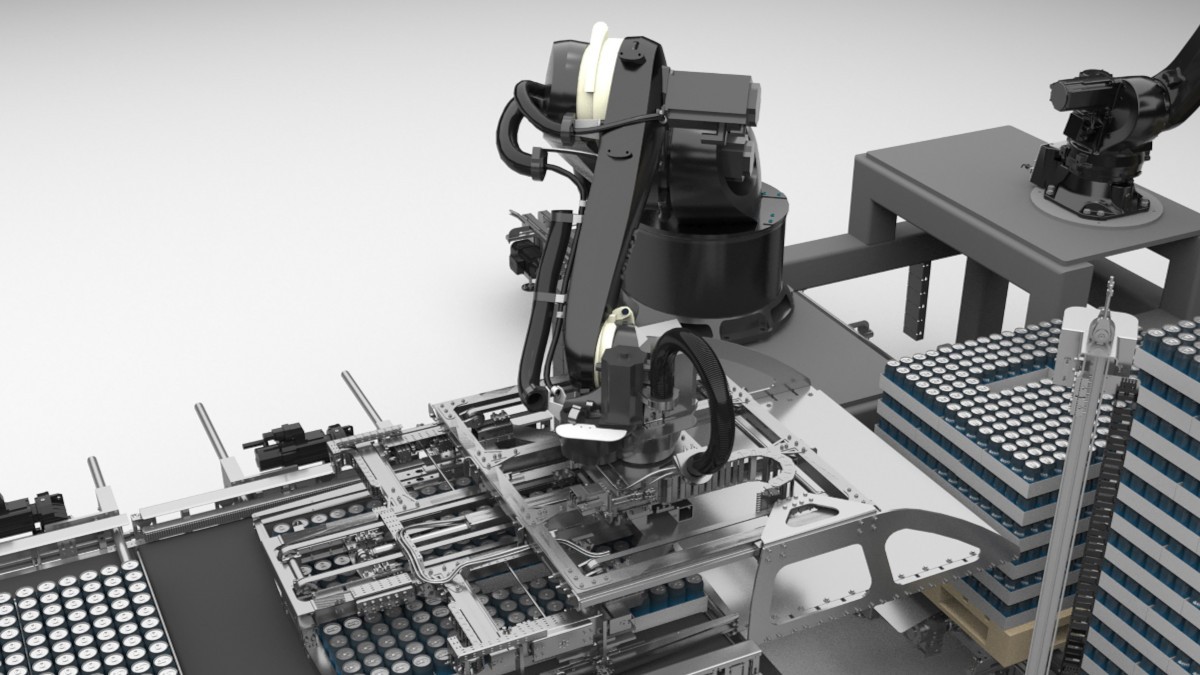

The palletiser's grouping system is equipped with the new InnoPET iflex option, which enables fully automatic format changeovers. Furthermore, this technology allows for the gentle processing of various sustainable packaging solutions such as PaperPack, KHS NMP (Nature MultiPack) and trays without film. "When changing formats, the operator need only select the configuration on the HMI. The robots independently select the appropriate gripper and exchange it," explains Kretschmann. The high degree of automation has a positive effect on the efficiency, safety and speed of format changes. It also reduces the workload for the operator.

The Innopal PLR is designed with the latest generation of robots for a throughput of up to 650 layers per hour for PET and cans for high-performance applications. Copyright: ©Jan Schwerdtfeger

Cans, PET and glass

The plant manufacturer also placed great importance on safety in the further development of the pallet transport system to the Innoline PTR Series II. "Among other things, we have thoroughly assessed and reduced all crushing and shearing points in both transport and the surrounding area. It is particularly important to us that the Innopal PLR meets the highest occupational safety standards. In addition, all conveyors in the new concept are frequency-controlled and offer extended diagnostics for higher system availability," emphasises Kretschmann. The line-compatible palletiser handles the three classic container segments – cans, PET and glass – as well as all common pallet formats. Furthermore, the robotics solution is designed for durability and future-proofing and requires little maintenance. The optional intermediate layer processing is also carried out by a robot application.