Energy efficiency in the baked goods industry

New requirements under the Energy Efficiency Act

There is considerable interest in the baked goods industry in reducing energy consumption. With the Energy Efficiency Act (EnEfG) coming into force in November 2023, legislators are placing even greater emphasis on reducing greenhouse gas emissions. In addition, there is intense competition at the point of sale in the industry, which means that producers are under constant cost pressure if they want to remain competitive. Up to 60 percent of energy consumption in food processing plants is accounted for by heating and cooling processes, meaning that efficiency improvements and reductions in the carbon footprint have the greatest impact in this area.

Platform for waste heat

Small and medium-sized manufacturers, which are typical in the baked goods industry, are also affected by the provisions of the Energy Efficiency Act. They will face new obligations and will have to take measures such as waste heat recovery. And that means: If companies consume more than 2.5 gigawatt hours of final energy per year, which is already the case in large bakeries with a corresponding number of branches, they must draw up concrete, feasible implementation plans within three years.

Leading the way in this context: Section 17 of the Energy Efficiency Act (EnEfG) provides for the creation of a "waste heat platform", which went live on 15 April 2024 and is one of the key instruments of the Act. In the spirit of a waste heat register, the platform serves to exchange information and network companies and energy suppliers. In particular, the platform should be used when the waste heat generated cannot be avoided or reused within the company. This topic is gaining considerable momentum in the baked goods industry. This is because: Large bakeries produce not only a lot of bread, but also a lot of waste heat. By using it efficiently, companies can comply with legal requirements and achieve significant cost savings.

GEA develops tailor-made solutions that not only optimise efficiency but also meet the growing challenges of energy reduction. Copyright:© GEA

The key to greater energy efficiency

A range of effective measures and tools are available to companies for reducing energy consumption. GEA has developed a structured approach for this purpose, which has been validated by TÜV Rheinland and consists of two steps. In an initial assessment phase, known as Add Better Consulting, the energy experts work with the customer to analyse the current state of production. This data is used to calculate specific energy requirements and design improvements that fully exploit every single optimisable process, every machine upgrade and every more environmentally friendly replacement solution.

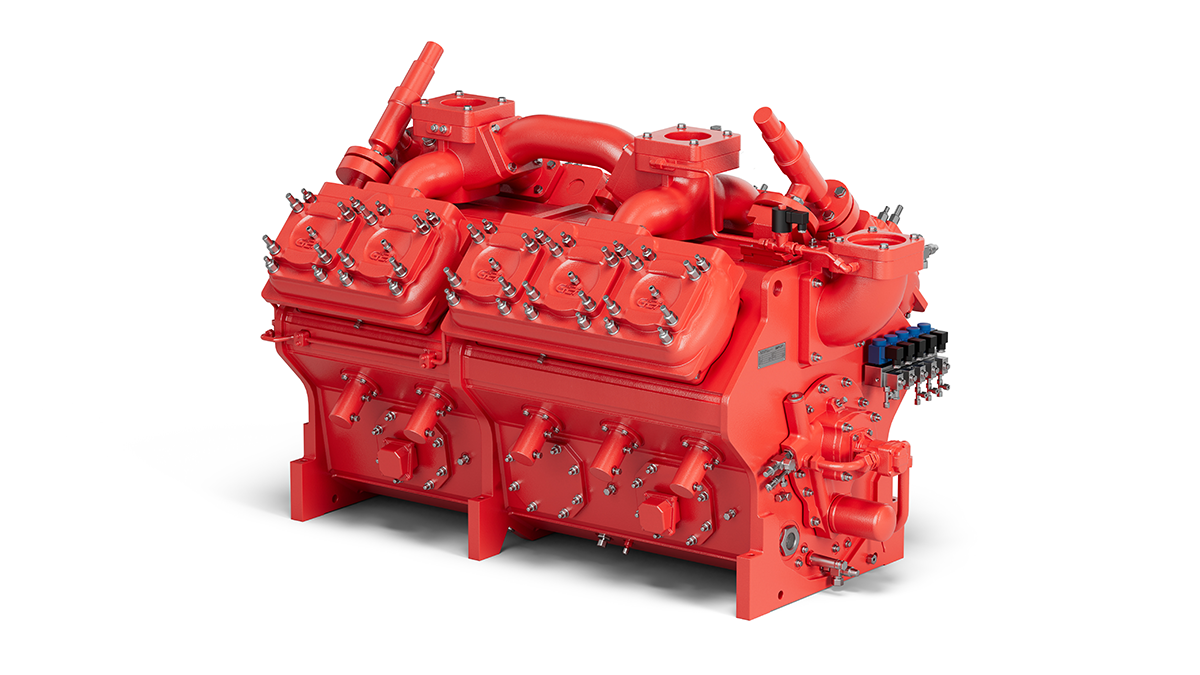

"If necessary, we can also start from scratch and work with the customer to develop a decarbonisation strategy and roadmap for the entire company," emphasises George Shepherd, Global Technical Sustainability Manager at GEA. In the second phase, the actual measures in production are then implemented with GEA NEXUS. During this implementation phase, optimisation takes place in the desired or necessary steps – "the first may be the integration of heat pump technology into the production process to ensure that energy is recycled and not wasted," says Shepherd, giving an example. A heat pump solution based on GEA V XHP piston compressors makes it possible to extract and amplify the low-grade heat from the refrigeration systems that would otherwise be unusable, and then use it for water heating.

Making clever use of cooling solutions and their waste heat

With its NEXUS concept, GEA focuses on integrating processes and utilities (cooling and heating) in order to reduce energy consumption, improve the carbon footprint and cut costs in the food industry. "At its core, NEXUS is about taking a holistic view of heating and cooling requirements. The individual process phases with their respective temperature requirements and phase changes in the production process, as well as the technical and process-related parameters, are examined from the outset and reviewed together with the manufacturer to find the most energy-efficient solution possible," explains Shepherd.

The background: Sooner or later, most applications in food processing require cooling. At the same time, processes such as wash-down and clean-in-place require a considerable amount of heat. Shephard says: "The highest heat requirements are found, for example, in processes where boilers are used to cook or pasteurise products. These are then cooled down again by a refrigeration system, which can lead to massive energy waste." This almost always leads to the conclusion that "a resource-saving heat pump from GEA is an important link in the chain, as it picks up low-temperature heat and heats it to a usable high temperature." A heat pump can raise the temperature of waste heat to 90 degrees Celsius and higher, enabling it to be fed back into the process in a cycle. Reusing this waste heat reduces the heat required from other sources, such as industrial ovens powered by fossil fuels. In many cases, these can be completely eliminated or replaced with electric models.

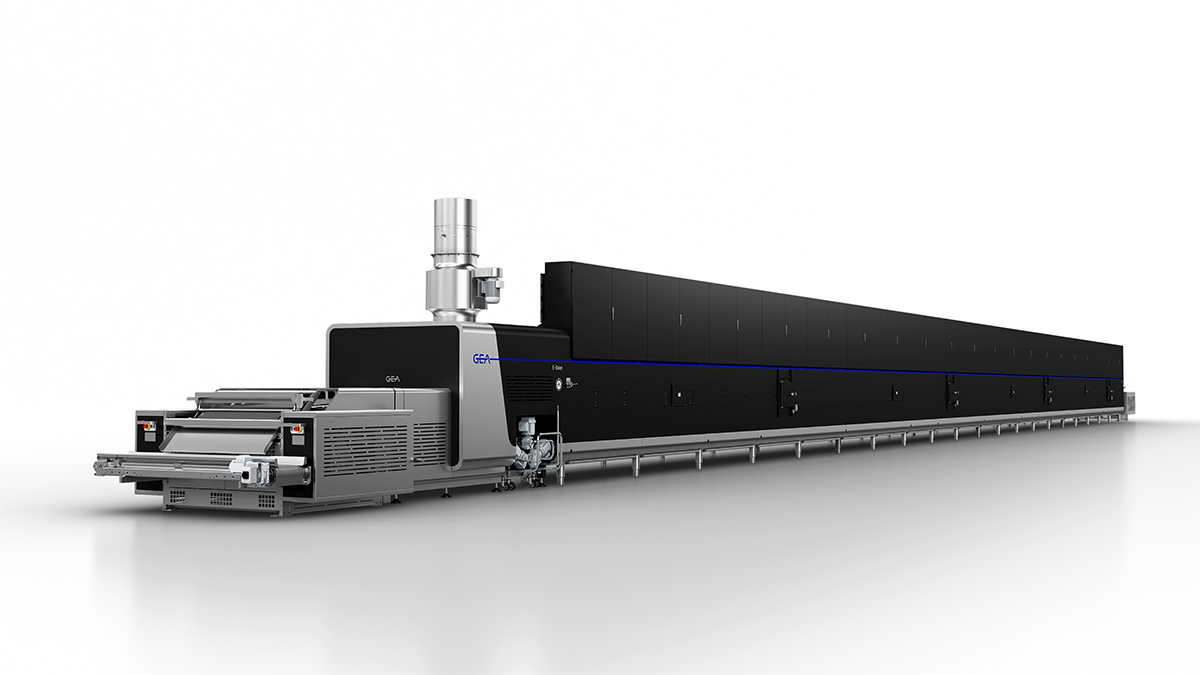

The new E-Bake G2 tunnel oven from GEA. Thanks to its design, which is optimised for electric operation without gas, it significantly reduces energy consumption in industrial baking. Copyright:© GEA

Electric tunnel oven minimises heat loss

The E-Bake G2 is a new electric industrial oven from GEA that has been developed with a focus on improved energy efficiency and optimised process control. The new oven is another step towards moving away from gas-based systems and enabling more sustainable baked goods production. Designed for the production of hard biscuits, soft biscuits and crackers, the E-Bake G2 offers improved air flow and flexible modules in a compact space. Its design is optimised for electric operation without gas, enabling a significant reduction in CO₂ emissions while delivering precise, reproducible baking results. The baking chamber has been designed with a reduced internal volume. This minimises heat loss and positions the heating elements closer to the product, resulting in improved thermal efficiency. The integration of micro-convection technology with local airflow systems ensures even heat distribution and reduces temperature differences across the entire baking surface.

Several configurations of heat transfer zones are available for the E-Bake G2, including electric radiation heating, electric convection heating, combinations of radiation and air turbulence, and other hybrid, highly flexible configurations of the above variants. Furthermore, thermal bridges were minimised. In addition, a new arrangement of electrical resistors supports targeted heat generation, contributing to a potential reduction in energy consumption of up to 40 percent compared to the gas-powered counterpart of the previous generation.

GEA's technology offering includes versatile process lines for baked goods. Copyright:© GEA

Focus on market requirements

"Our voice-of-the-customer surveys showed growing interest in sustainable baking solutions, especially electric baking," confirms Marco Girimondo, Product Manager at GEA. "However, customers are facing high operating costs due to energy prices and investment costs for upgrading their plant infrastructure. The E-Bake G2 addresses this challenge by significantly reducing energy consumption and lowering both installed power and total operating costs compared to conventional electric ovens.

George Shephard also confirms: "This significantly improves the efficiency and sustainability of the entire baking process." By involving an interdisciplinary team of experts, consisting of sustainability, refrigeration technology and process specialists, GEA can leverage its unique expertise at the start of the planning phase to optimise the entire processing line, thereby achieving significant cost, energy and emission reductions. "Our holistic NEXUS concept works for every application in projects of any size. It doesn't matter whether it's a greenfield or brownfield project, or whether a specific temperature is required for baking bread or a different temperature for cooling cakes," concludes Shephard.

For additional information: www.gea.com