Friction-based grippers offer advantages

Ms Düngfelder, the tasks performed by robotics include rapid sorting, portioning and packaging. But how can breakage or damage to sensitive foods be prevented ...

Martina Düngfelder: Automation in the food industry must always be tailored to the product being handled. To maximise the efficient use of robot technologies in the food industry, choosing the right gripper technology is of central importance. Stäubli offers a very open system that allows the control of many components, thereby ensuring a high degree of flexibility in robotics.

What technologies are used for gripping sensitive products?

Friction-based gripping techniques, such as vacuum gripping with Venturi nozzles, offer significant advantages, particularly in hygienically sensitive areas. These technologies enable gentle, precise handling, which is crucial for processing sensitive foods. Another aspect is the integration of image processing systems. The combination of precise mechanical gripper technology and advanced image processing using artificial intelligence enables automation that is both efficient and safe.

Two TS2-60 robots suitable for use in real-life situations carry out the picking and sorting of large quantities of chicken breasts at high speed – thanks in part to Oxipital's AI-supported image processing technologies. Copyright: ©Stäubli

What specific advantages does the combination of robotics and image processing offer?

The systems can be used to monitor quality processes – for example, to ensure that only baked goods that actually meet the required standards are processed and packaged in a large bakery. Intelligent AI cameras open up new possibilities here, especially when handling natural products that vary greatly in shape, texture and size. And last but not least: The use of modern vision technologies significantly reduces the teaching effort required for the robots.

Which vision systems can be coupled with Stäubli robots?

Our open controller technology makes it easy to integrate a wide range of vision technologies available on the market, such as 2D, 3D and AI-based cameras. This enables our four and six-axis robots to detect the products in their correct position and grip them precisely. With self-learning image recognition, AI cameras enable more efficient and flexible adaptation to the specific characteristics of products, resulting in improved automation.

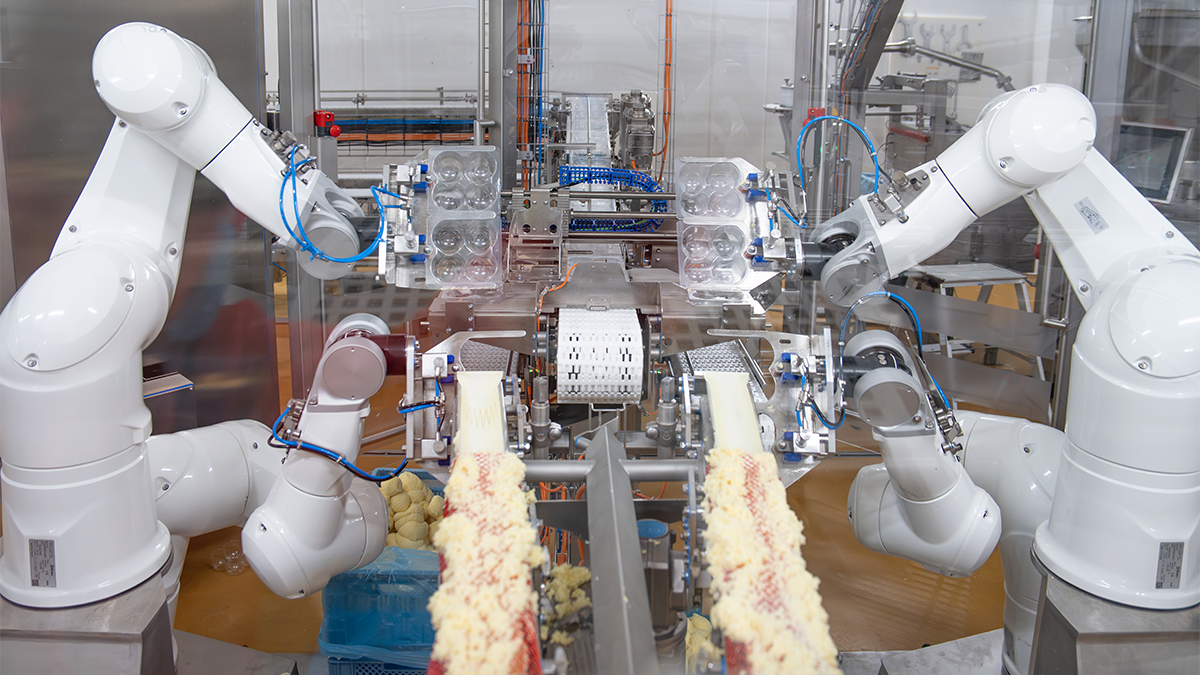

Four TX2-90 he robots in Stericlean design pack up to 160 rolled dumplings per minute in blister packs at Friweika in Saxony. Copyright: ©Stäubli

This is particularly advantageous in the food industry, where the diversity of natural products places complex demands on inspection and picking applications ...

The American company Oxipital AI, one of our partners, is a pioneer and market leader in this field. The picking and sorting of chicken breasts, a task that was previously carried out exclusively by hand, also demonstrates the importance of partnership-based cooperation in the area of food safety. Two Stäubli TS2-60 robots perform this task quickly and with exceptionally high output thanks to AI-supported Oxipital AI image processing solutions.

Added to this are the production environments, which are often characterised by high humidity and splash water. How does this affect your robots?

A major advantage is the mechanical design of our HE robots, where HE stands for Humid Environment. Thanks to their fully enclosed construction, hygienic design and resistance to cleaning procedures, HE robots now set the benchmark in many sensitive applications. In other words, wherever high standards of hygiene and cleanliness are required in production environments. The excellent cleanability of our robots is a major USP and enables easy maintenance and long-lasting, hygienic operation of the line.

With its four-finger gripper, a Stäubli TX200 picks up four 12-kilogram sausage rolls and loads them gently and safely into the slicer at Kaufland Fleischwaren in Heilbronn, Germany. Copyright: ©Stäubli

When raw meat is being processed, it is particularly important that the entire process is carried out in accordance with the highest hygiene standards ...

With our HE robots, this is no problem at all, as we demonstrated at the recent Anuga FoodTec in Cologne. In one of our demo cells, the TS2-60 he and a TX2-60 he were used to handle chicken and beef using conveyor tracking technology. The TX2-60 he cut chicken legs and steak meat using a water jet unit from Swiss manufacturer Allfi. The pieces of meat were then transported by conveyor belt to the next station, where they were gripped by the camera-guided TS2-60 he and placed in the packaging.

How easy is it to adapt the robots to changing products or sizes, for example for small batch sizes or frequent product changes?

A sophisticated technical solution is crucial for mapping the entire product range of a food manufacturer, with sensor technology playing an essential role in guaranteeing precision and adaptability. AI-controlled camera systems enable flexible adaptation of production to changing product characteristics through real-time analysis and machine learning. This in turn allows dynamic process handling without compromising efficiency.

High-quality and reliable quick-change systems play an equally important role ...

For maximum multifunctionality and versatility, we offer our tool change systems as part of a modular concept. These allow customers to choose between configurable standard modules from the existing product portfolio and completely customised solutions. These systems enable quick and easy changes to the production line, minimising downtime and maximising flexibility. This is particularly relevant when demand for customised products and fast time-to-market is growing.

What technological trends do you see for food automation in the coming years?

The modern food industry is undergoing profound change as a result of digitalisation and automation, with key technologies such as artificial intelligence, machine learning, robotics, the Internet of Things and blockchain contributing significantly to this transformation. These technologies are not only crucial for optimising production processes and improving transparency in the supply chain, but also play a decisive role in ensuring efficiency and food safety.

Peeling and pitting avocados is challenging, but it can be done with Stäubli's hygienic six-axis robot and the robot cell developed by Kronen. 400 fruits can be processed per hour. Copyright: ©Stäubli

... and how is Stäubli preparing for this?

Increasing demands on cleanability, coupled with a greater focus on sustainability, are driving Stäubli to minimise its ecological footprint while significantly extending the service life of its robot systems. The HE series and AGV portfolio embody this integration by combining advanced technologies and practical applications to guarantee efficient workflows and flexible material transport. We also provide comprehensive solutions for intralogistics, ensuring smooth integration from the warehouse to production.

About Stäubli Robotics

Stäubli Robotics' unique product portfolio includes four and six-axis industrial robots, collaborative and mobile robots, and driverless transport systems. Stäubli's powerful, high-precision solutions enable customers in many demanding industries to master the challenges of Industry 4.0, even under highly specific manufacturing conditions.

Further information