Hygienic Material Flow without Contact

Contactless transport – more flexible than traditional conveyor technology

Requirements are increasing in the food industry: Hygiene, adaptability and an uninterrupted product flow are essential today. The solutions from Interroll and ek robotics offer scalable alternatives to stationary conveyor technology.

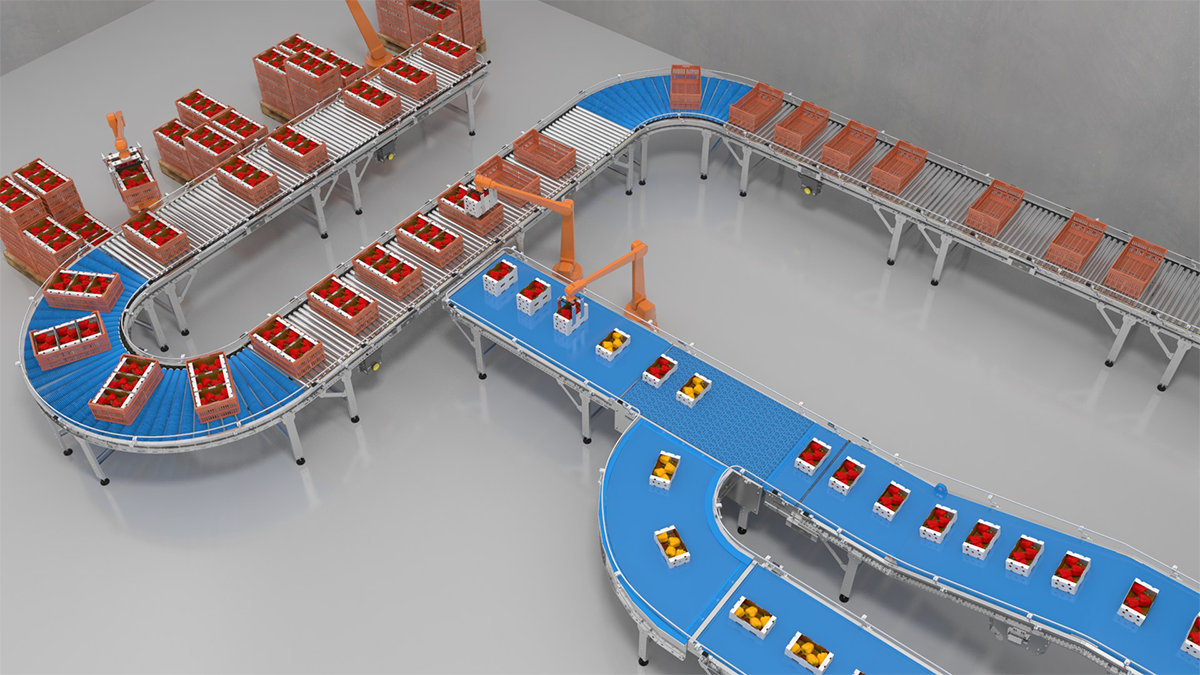

Interroll relies on the modular Special Hygienic Conveyor (SHC) system, which activates each conveyor zone only when needed thanks to separately controllable 24/48V drives. "Unlike conventional systems that operate continuously, we enable resource-saving, selective transport – without pressure build-up, quietly and with ease of cleaning," explains Dr Stephan Kronholz, Vice President Hygienic Solutions at Interroll. The stainless-steel system was specially developed for production areas with strict hygiene requirements.

ek robotics pursues a highly flexible concept: Standardized and customized automated guided vehicles move fully automatically along defined routes – precisely adapted to production requirements and environmental conditions. "Our driverless transport systems and transport robots offer maximum scalability and independence. They can be tailored precisely to sensitive processes such as those found in food production," emphasizes Ronald Kretschmer, Chief Sales Officer, CSO at ek robotics.

The SHC from Interroll saves energy through intelligent zone control with 24/48 V drives. Source: Interroll (Switzerland) AG

Efficiency gains through driverless and contactless systems

Interroll's SHC technology scores with zone-controlled logic: Conveyor areas are only activated when there is product contact. According to the company, this reduces energy consumption by up to 90 % compared to conventional 400-volt systems and extends the service life of components. Contactless separation prevents jams and collisions – the material flow remains stable and maintenance costs are reduced.

ek robotics also delivers measurable efficiency gains with its AGS. The transport robots operate independently of breaks or staff availability and significantly increase the cost-effectiveness of the sites. A real-life example: Arla Foods UK has 90 vehicles from ek robotics in operation, which move more than 200,000 litres of milk per hour fully automatically in the cold store. They increase organisation in block storage, reduce product damage and maintain delivery performance at a high level, adds the company's CSO.

Driverless transport system from ek robotics in use at Arla Foods UK: The custom-built transport robots move thousands of litres of milk around the clock – precisely, hygienically and efficiently. Source: ek robotics GmbH

Improved hygiene and safety during product handling

The SHC platform from Interroll meets the highest hygiene requirements: ISO 4 certification for clean rooms, a closed stainless-steel construction with rounded guides and patented seals ensure easy cleaning and protection against cross-contamination. Dr Kronholz emphasises: "No water remains in the rollers after washing, which makes our technology particularly safe for sensitive products."

The AGS from ek robotics are also designed for sensitive environments. Stainless-steel robots (see photo) are, for example, used in hygiene locks and clean rooms. "A leading milk producer has been using our solution for over 20 years to precisely supply individual ingredients for cheese production in the Rhine region," reports Kretschmer. Laser scanners and dynamic protective fields additionally ensure safe navigation in mixed working areas.

Integration in existing intralogistics structures

The areas of application for ek robotics' AGS solutions can also be flexibly expanded. New warehouses, shelving systems or production lines can be added at any time by extending the route travelled – even without interrupting operations. This is how you can successfully enter the world of future-proof, highly automated intralogistics.

With its SHC platform, Interroll offers a plug-and-play solution that can be flexibly integrated into existing conveyor systems. Straight track elements and curved or sloping sections can be combined individually. "Thanks to transition modules (Modular Conveyor Platform) with a small deflection radius, our systems fit into almost any environment," explains Dr. Kronholz.

Stainless-steel vehicle from ek robotics for hygiene-critical areas: This automated guided vehicle was custom-designed for use in cheese production and clean rooms. It's robust, easy to clean and fully automated. Source: ek robotics GmbH

Digitalisation as the key to intelligent material flows

Interroll has developed the IP 55 Multi Control controller, a system that supports all common industrial standards – from Profibus to EtherCAT (standards for data communication). Sensors and drives are integrated directly into the fieldbus level, and additional systems such as labellers or robots can be integrated without costly retrofitting. With the digital Interroll Layouter tool, project planning is made more efficient – from planning to commissioning.

ek robotics goes one step further with its cloud-based solution SARA (Smart Analytics Reporting App): It analyses all system data in real time and generates recommendations for future optimisations. Thanks to intelligent system networking between the AGS control system, warehouse management, conveyor technology and vehicle software, AGS prevent incorrect deliveries and ensure continuous, transparent logistics processes.

Ronald Kretschmer, CSO at ek robotics Source: ek robotics GmbH

Future trend: Contactless intralogistics as the new standard

For Dr Kronholz, one thing is certain: "Sustainability, hygiene and efficiency will remain the driving forces in intralogistics – and 24/48 V technology-based, accumulation-free roller conveyors are the answer." Decentralised control, low emissions and easy integration make the SHC system a building block for future-proof production environments.

ek robotics also sees driverless systems as an established standard: They reduce dependence on personnel, secure processes around the clock and can be flexibly adapted. "More and more companies are recognising that AGS are not only efficient, but also sustainable and crisis-proof – especially in the context of Industry 4.0," explains Ronald Kretschmer.

Both companies agree: Contactless intralogistics is becoming the new standard – combining hygiene, efficiency and process reliability in increasingly automated food production.

Contact for additional information:

Dr. Stephan Kronholz

Vice President Hygienic Solutions

Interroll (Switzerland) AG

Via Gorelle 3

6592 Sant'Antonino,

Switzerland

www.interroll.com

Ronald Kretschmer

Chief Sales Officer

ek robotics GmbH

Oberwerder Damm 11

20539 Hamburg

E-Mail:

info@ek-robotics.com

https://ek-robotics.com/