Greater Efficiency Meets Flexible Consumption

Food industry in the energy transition

Each energy source causes different emissions. Just as the shares of the various fossil and renewable energies in the electricity generation mix fluctuate constantly, so does the Grid Emission Factor (GEF), i.e. the specific CO2 emission of the electricity. From an ecological perspective, a low GEF is desirable. On the other hand, the respective exchange price of the electricity is an important economic incentive. The InES investigations revealed a positive correlation between the two key figures, i.e. low specific emissions usually go hand in hand with low electricity exchange prices. To take advantage of this correlation and increase their system efficiency, food companies can deliberately shift the operation of consumers to low-emission times. In times of high emissions, self-generated electricity can be increasingly used. An overview of the exact processes is essential for a system-efficient energy concept. This is complemented by the increased use of renewable energies and the conversion to energy-saving individual measures.

Optimised operation of cleaning systems

Cleaning processes, as a cross-sectional technology in the food industry, have a special role to play in stabilising energy costs for the industrial process. There is efficiency potential in CIP cleaning systems, on the one hand, in the insulation of pipelines and tanks and, on the other hand, in the preheating of the pipelines using waste heat. In addition, the waste heat from liquid waste materials, i.e. water, caustic solutions, acids and cleaning agents that are discarded in the cleaning process, can be used to preheat new cleaning agents or fresh water. There is a large reservoir of heat here, but it only accumulates in many small partial quantities during the short sewer phases. These would have to be collected in a separate tank before waste heat utilisation. In the study, which was carried out on a CIP line at the Zott dairy, a high theoretical potential of up to 57 MWh resulted in the one-month observation period due to the high volumes, despite relatively low temperatures of 25 to 35 °C. Heat quantities with a low temperature level can be raised to higher temperature levels with low CO2 emissions by means of heat pumps and renewable electricity. Then they can also be used for reheating acid and caustic solution and the system flexibility increases. According to the study, postponing cleaning procedures - insofar as it is possible - brings greater flexibility to the energy supply, however it represents an intervention in the production processes, which is often not practicable.

Within the framework of the system efficiency approach, a higher energy demand for renewable electricity at the right time can also lead to increased benefits.

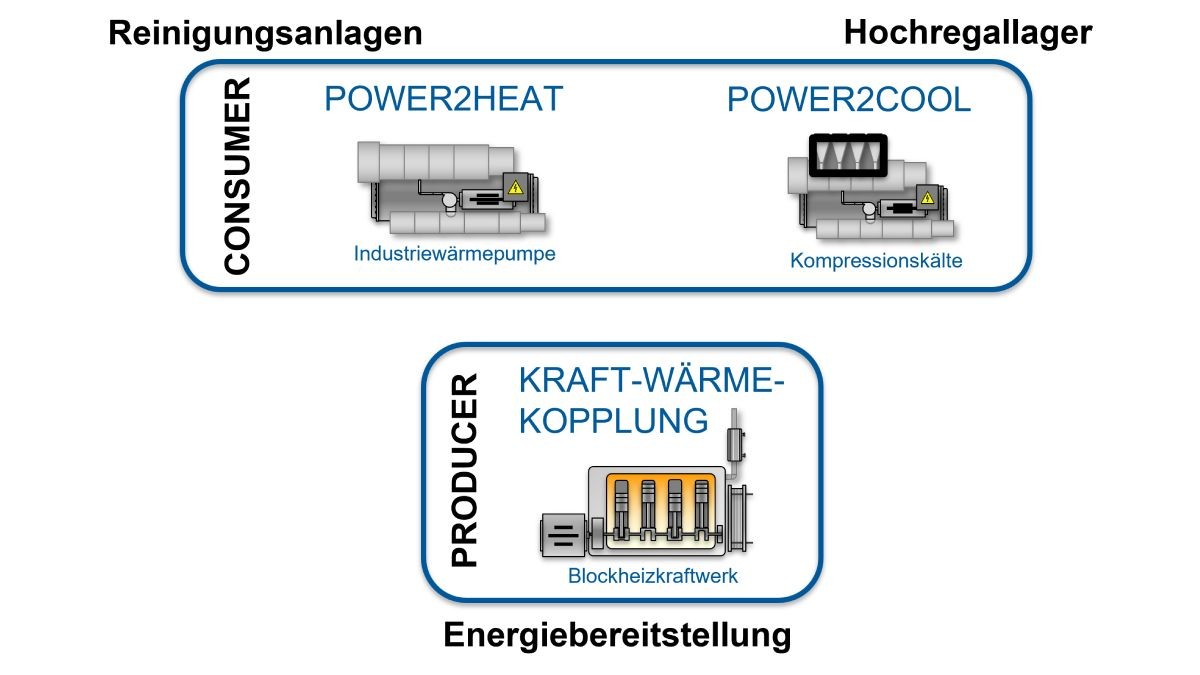

More efficient use of combined heat and power plants

Using the example of the medium-sized Andechser dairy Seitz, a detailed techno-economic analysis of the more efficient use of CHP units was carried out by means of specially created flexibility models. One objective was to investigate concepts that focus on the greatest possible system efficiency instead of the usual high self-sufficiency in heat and electricity: A CHP produces and feeds the electricity completely into the public grid, while little RE is available. The CHP unit and the heat reservoir tend to have to be larger than in the case of self-supply of electricity. The electricity for production and cooling comes entirely from the public grid.

A comparison of the two models showed that for 2020, with relatively favourable stable prices and fixed preconditions, none of the flex variants investigated achieved lower energy supply costs than the self-supply concept. In 2022, on the other hand, with its extreme framework conditions, all flex variants achieved lower energy supply costs than the self-supply concept. The amortisation periods are also better. With increasing price volatility and uncertain framework conditions, flexible concepts can therefore increase the resilience of the operational energy supply and contribute to risk minimisation.

Potential of a more flexible cold chain

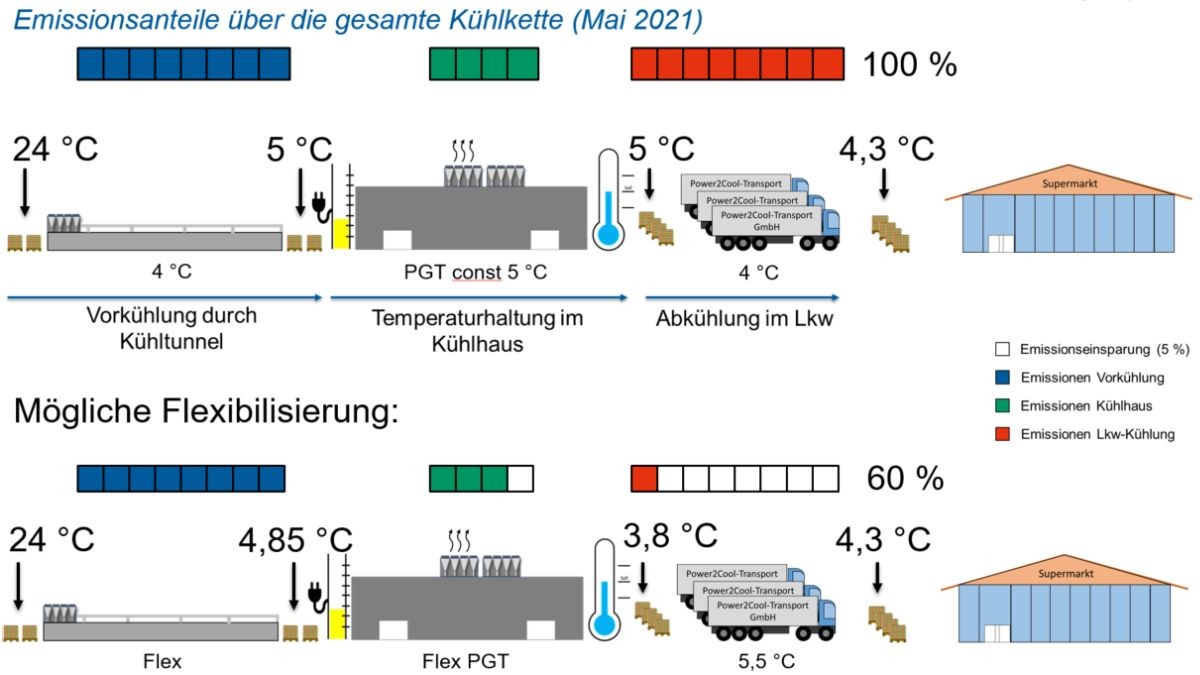

To make the cold chain more flexible, the air temperature in the cold storage facility is reduced when specific emissions are low, increasing the electrical reference power. In the case of high emissions, which are often accompanied by a higher electricity exchange price at the same time, the refrigeration system is switched off until the specified air temperature is reached. Then refrigeration is continued to ensure the quality of the product. The variation of the air temperature in the cold storage facility can be higher than the permissible variation of the products in the cold storage facility because they act as a temperature buffer to a certain extent. In this way, the electrical reference power can be reduced or increased depending on the share of RE in the electricity mix. Emissions are then reduced when electricity is purchased. However, any flexibilisation of one link in the cold chain has an impact on the other steps, as the product temperature changes. This can shift the cooling demand to subsequent stations and have a negative impact on energy consumption during truck transport. Conversely, the cooling requirement for truck transport can already be met in the cold storage facility:

Truck transport can be made more flexible in terms of energy by varying the interior temperature. The temperatures depend on factors like the duration of the journey, the starting time or the time of year. If, for example, the target is a delivery temperature of 4.7 °C, this can be achieved with an internal temperature of 4 °C and a product temperature of 5 °C, or with an internal temperature of 6.5 °C and a product temperature of 3.75 °C. According to the model calculations, up to 90 % of the transport-related emissions can be saved for the period examined if the product temperature is reduced accordingly. Calculated over the entire cold chain, savings of around 40 % were achieved, a large part of which was accounted for by truck transport.

Example of possible emission reductions through targeted flexibilisation of the cold chain.

Dairy industry can take advantage of many opportunities individually

Overall, the milk-processing industry is well positioned to play an active role in shaping the energy transition. There is a lot of potential to achieve a significant reduction in CO2 with measures individually adapted to the respective operation, thereby saving money and increasing the security of supply.

Within the framework of the system efficiency approach, a higher energy demand may also be permissible at the right time because the benefits clearly outweigh the costs. One example is the Power2Cool approach, in which compression cooling from renewable electricity is used specifically for deeper cooling of a high-bay warehouse. On the generation side, a sufficiently dimensioned CHP unit can reduce emissions, stabilise energy costs or reduce external energy demand, depending on the mode of operation and heat utilisation concept. The central instrument for increasing system efficiency - not only in the milk processing industry - lies in the detection, targeted adjustment and intelligent use of the existing temperature levels.

Prof. Dr.-Ing.

Uwe

Holzhammer

Institue for new Energy-Systems (InES) at the TH Ingolstadt

Tel. +49 841 9348-5025

Write an e-mail